The Role of Downhole Tools in Geothermal Energy Exploration A Step-by-Step Guide

/As the world pivots towards sustainable and renewable energy solutions, the earth's internal heat emerges as a key player in the global energy landscape. Harnessing geothermal energy involves a sophisticated dance beneath the surface, where downhole tools take center stage. In this journey into the depths, we'll explore how these tools navigate the complexities of geothermal exploration, from the initial site assessment to the implementation of Enhanced Geothermal Systems (EGS).

Figure 1: Geothermal Drilling with Rockpecker Tools

In this step-by-step guide, we'll unravel the key stages of how downhole tools contribute to the harnessing of this abundant and clean energy source, as well as the types of downhole tools commonly used for each stage in geothermal energy exploration:

1. Initial Site Assessment

The journey begins with a comprehensive site assessment. Downhole tools aid in geological surveys and subsurface investigations to identify potential geothermal reservoirs. Tools like gamma ray sensors, resistivity meters, and temperature probes help geologists analyze the subsurface conditions and determine the viability of a site.

• Gamma Ray Sensors: Measure natural gamma radiation to identify different rock formations.

• Resistivity Meters: Determine the electrical resistivity of subsurface materials, aiding in geological analysis.

• Temperature Probes: Measure subsurface temperatures to identify potential geothermal reservoirs.

2. Drilling Operations

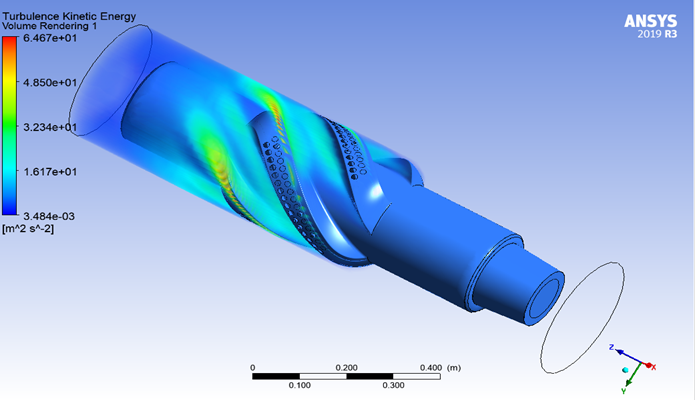

Once a promising site is identified, drilling operations commence. Downhole tools like rotary steerable systems and mud motors facilitate the drilling process. These tools precisely control the drill bit, ensuring optimal penetration rates and allowing geologists to navigate challenging subsurface conditions.

• Rotary Steerable Systems: Provide real-time control of the drill bit direction for accurate wellbore placement. • Mud Motors: Convert hydraulic energy from drilling fluid into mechanical energy to rotate the drill bit.

3. Reservoir Evaluation

As drilling progresses, downhole tools come into play for reservoir evaluation. Logging tools, including electromagnetic and sonic sensors, are deployed to gather data about the geothermal reservoir's characteristics. This data is crucial for understanding the reservoir's temperature, pressure, and fluid composition.

• Electromagnetic Sensors: Measure the electromagnetic properties of rocks to identify reservoir characteristics.

• Sonic Sensors: Provide information about the composition and porosity of rocks.

4. Well Completion

After successful drilling and reservoir evaluation, downhole tools contribute to the well completion process. Tools like packers, valves, and cementing equipment ensure that the well is sealed and secure. This step is essential for maintaining the integrity of the well and preventing any potential environmental impact.

• Packers: Seal the annular space between the casing and the borehole wall to prevent fluid migration.

• Valves: Control the flow of fluids within the wellbore.

• Cementing Equipment: Ensures proper sealing of the well to prevent environmental contamination.

5. Fluid Extraction

The heart of geothermal energy lies in fluid extraction from the reservoir. Downhole pumps and turbines are employed to bring the hot fluid to the surface. This fluid, typically a mix of water and steam, carries the Earth's heat and is used to generate electricity through surface power plants.

• Downhole Pumps: Lift geothermal fluids to the surface.

• Downhole Turbines: Convert the energy of flowing fluids into mechanical energy.

6. Monitoring and Maintenance

Once the geothermal power plant is operational, downhole tools continue to play a role in monitoring and maintenance. Sensors and gauges are strategically placed downhole to provide real-time data on good performance, enabling engineers to make informed decisions about maintenance activities.

• Downhole Sensors and Gauges: Measure parameters like pressure and temperature for real-time monitoring.

• Acoustic Sensors: Detect anomalies and potential issues within the wellbore.

7. Enhanced Geothermal Systems (EGS)

Downhole tools are instrumental in implementing Enhanced Geothermal Systems (EGS) for locations with lower natural permeability. EGS involves creating artificial reservoirs by stimulating the subsurface using hydraulic fracturing or other methods. Downhole tools are crucial for designing and executing these stimulation processes.

• Hydraulic Fracturing Tools: Create fractures in the rock to enhance permeability.

• Injection Pumps: Introduce fluids into the reservoir to stimulate heat exchange.

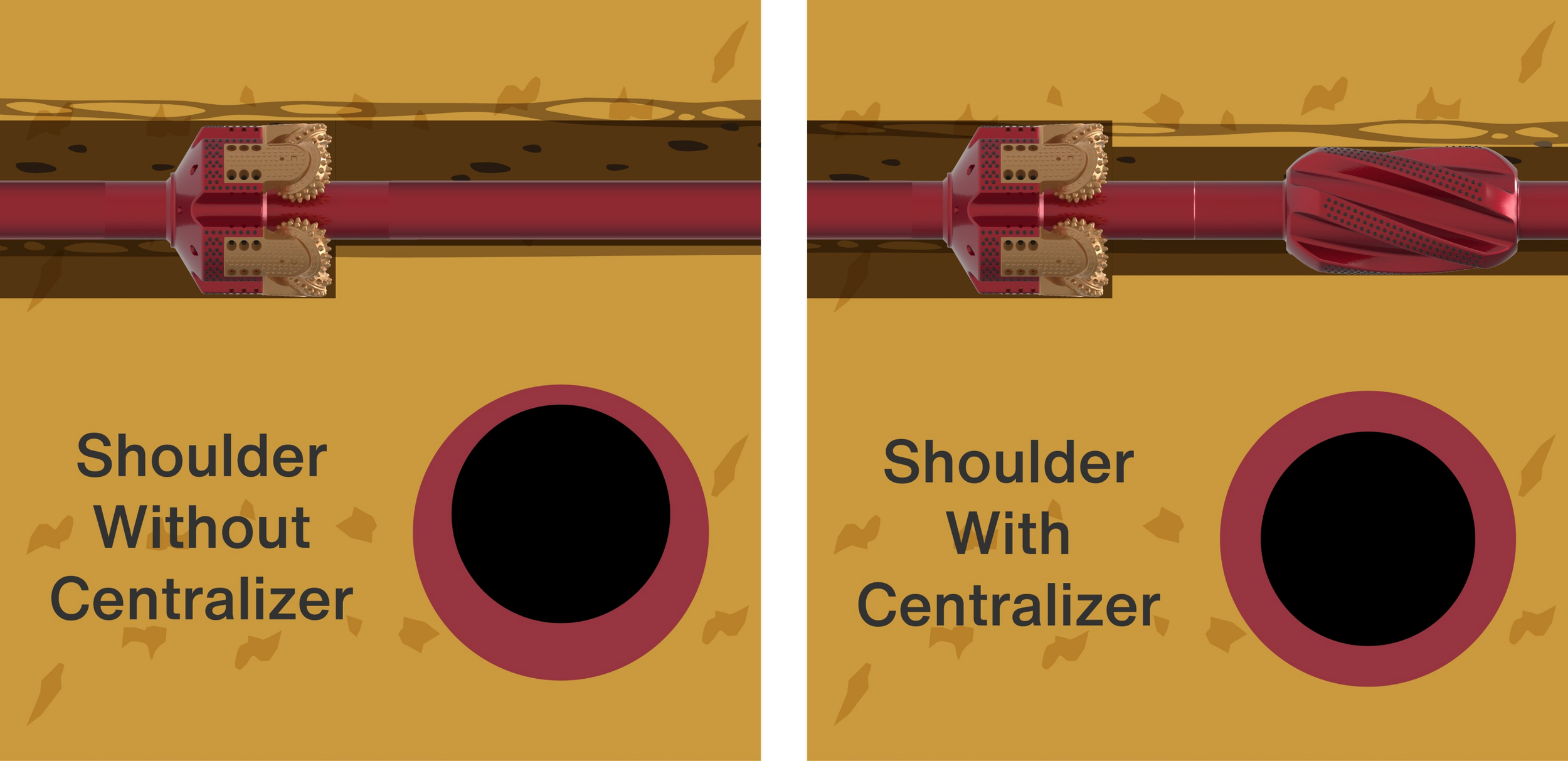

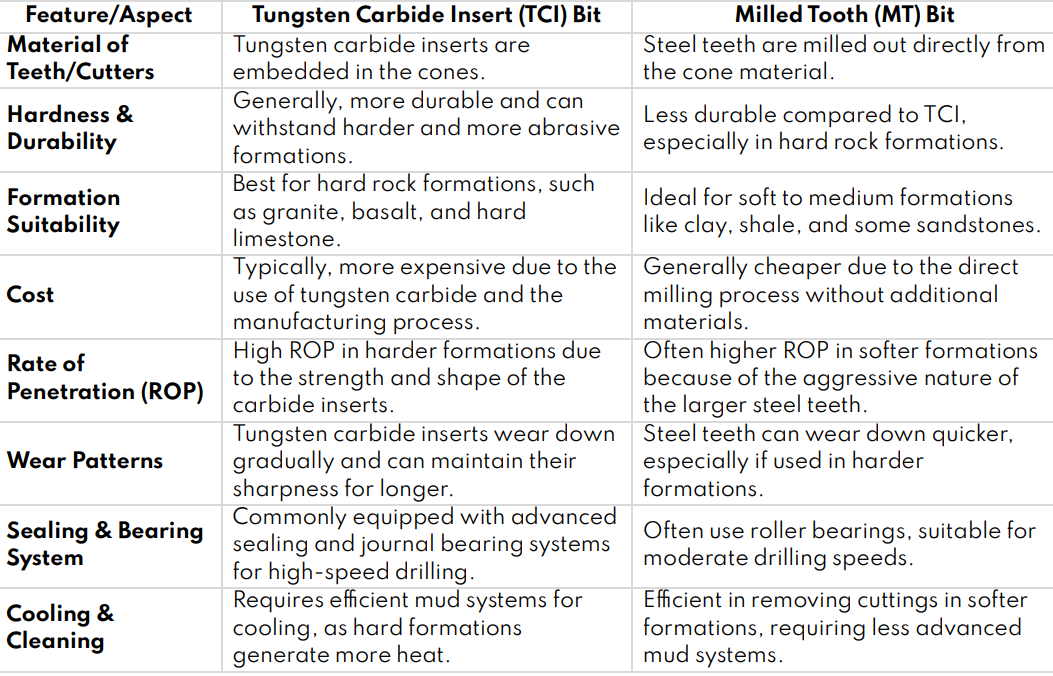

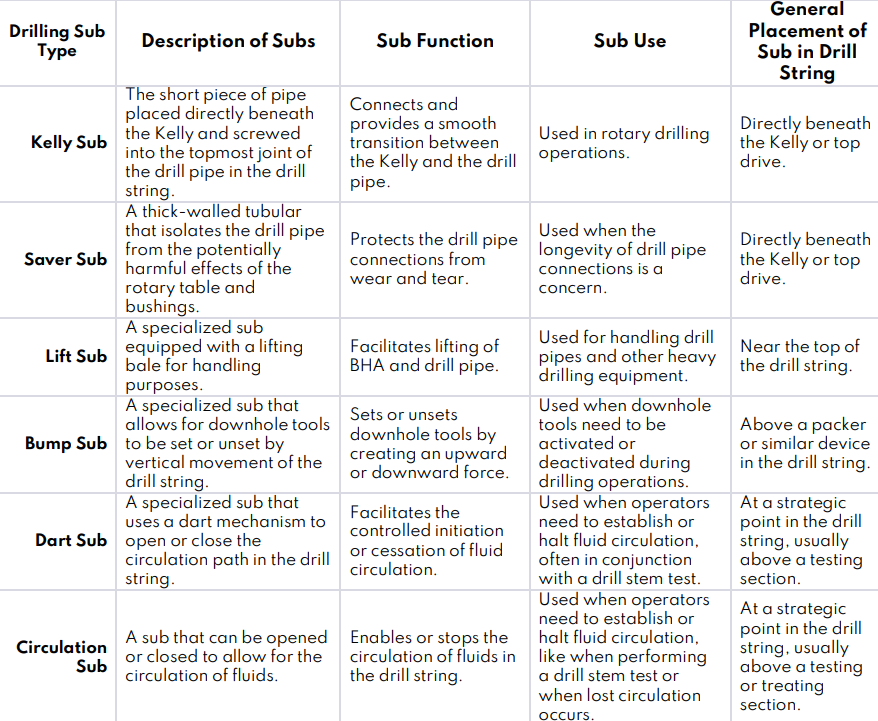

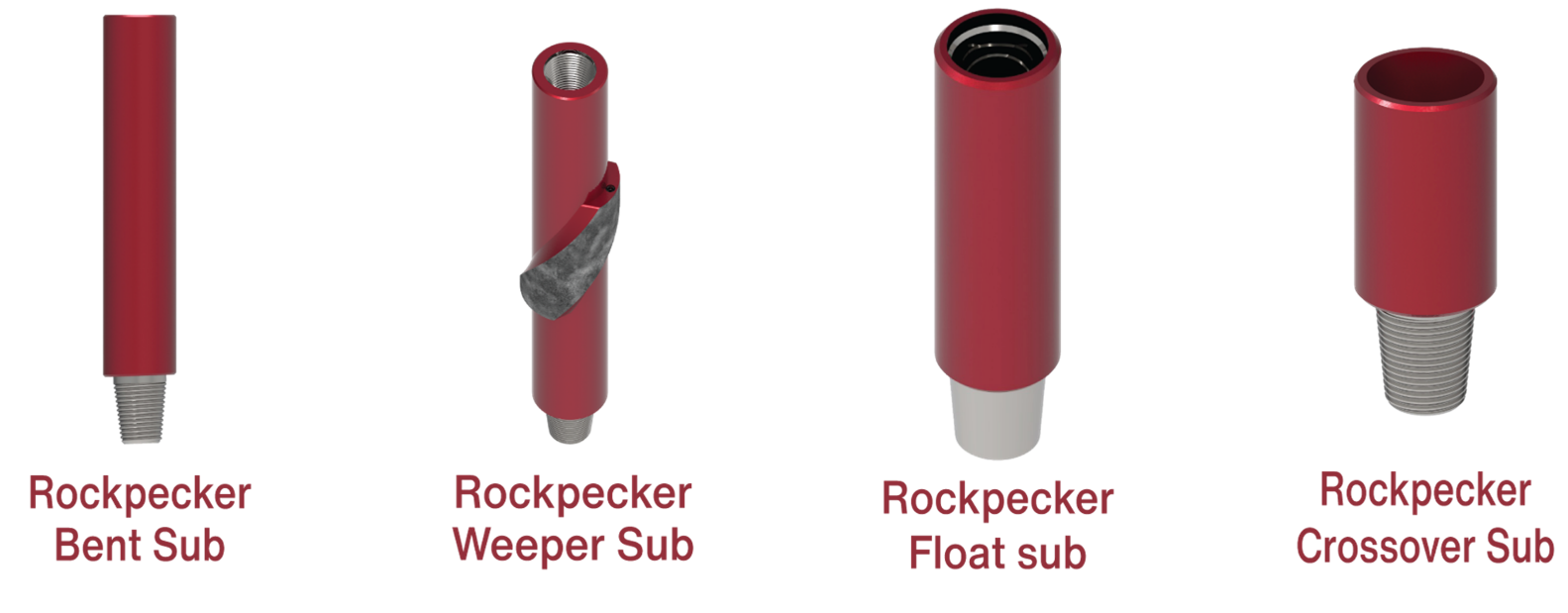

In geothermal drilling, a versatile range of tools, including bits, reamers, centralizers, and accessories, is meticulously designed to meet the diverse challenges posed by geological conditions.

Rockpecker, the trusted name in geothermal drilling tools, offers a variety of these tools in various sizes that demonstrate excellence in design and functionality.

Figure 2: Rockpecker Bits- Popular Sizes

These tools provide tailored specifications that are ideal for their distinct functions in extraction and exploration. The size range encompasses different diameters and is heavily reliant on drilling requirements and geological subtleties.

Rockpecker, a leading manufacturer and provider of geothermal drilling tools, offers a varied selection of these tools in different sizes, showcasing a commitment to design excellence and functionality.

For instance, bits are available in sizes tailored for precision or enhanced fluid circulation, while reamers and centralizers cater to specific well dimensions and casing diameters, respectively however please note that the sizes mentioned are general ranges, and actual sizes may vary based on specific project requirements and tool specifications

Figure 3: Downhole Drilling Tools for Geothermal Drilling

Conclusion: Unleashing Earth's Inner Heat

In the realm of geothermal energy exploration, downhole tools are the unsung heroes, enabling precise and efficient operations at every stage. From the initial survey to harnessing the Earth's inner heat for electricity generation, these tools contribute to a sustainable energy future. As technology advances, the role of downhole tools in geothermal exploration is set to become even more sophisticated, unlocking new frontiers in clean and renewable energy.