Why Your Bits Are Failing Early — And How to Fix It

/When project managers talk about “unexpected costs,” drillers usually know exactly what that means: bits that fail before their time, trips that weren’t planned, and tool replacements that weren’t in the budget. It doesn’t matter whether you’re drilling water wells in remote terrain, steering HDD in an urban choke-point, pushing through abrasive sandstone in a geothermal borehole, or chasing depth in a high-pressure oil & gas formation—premature drill bit failure is the silent budget killer that chips away at margins long before anyone notices.

What starts as “slightly slower ROP than expected” ends up becoming:

- Unplanned tripping time

- Increased fuel & mud consumption

- Higher torque & drag loads

- Damaged drill strings

- Lost cutters or broken blades

- And sometimes, catastrophic stuck-pipe events

Figure 1:Why Your Bits Are Failing Early — And How to Fix It

The good news? Most premature bit failures are preventable if you understand why they occur and how to diagnose the root cause—systematically, not guess-and-check.

This guide walks step-by-step through the process professionals use in drilling operations globally to assess bit failure, optimize tool selection, and avoid sinking money into the same mistakes again.

Step 1: Identify the Early Warning Signs

Bit failure rarely happens “suddenly.” It begins with small performance deviations that drillers often ignore because they seem manageable.

Common early indicators & ignoring these signs is like ignoring a “check engine” light—eventually the machine fails.

Figure 2: Common early indicators

Step 2: Conduct a Structured Bit Inspection After Pull Out

A good post-run inspection is worth more than ten assumptions. Every driller should establish a structured procedure for examining the bit. The 6-Point Bit Inspection Checklist

- Cutting Structure o Look for chipped, broken, or polished cutters. o Identify thermal damage (blue discoloration).

- Blades & Junk Slots o Check for erosion, impact dents, plugged junk slots.

- Gauge Pads / Gauge Inserts o Evaluate gauge wear—an extremely common cause of deviation issues.

- Nozzles & Hydraulic Ports o Blockage or incorrect nozzle selection often causes early damage.

- Shank / Connection Condition o Inspect for cracks, deformation, galling, thread damage.

- Bit Body (Matrix or Steel) o Steel body erosion patterns reveal fluid mismanagement or improper WOB. o Matrix body breakouts often suggest impact on stringers or inclusions.

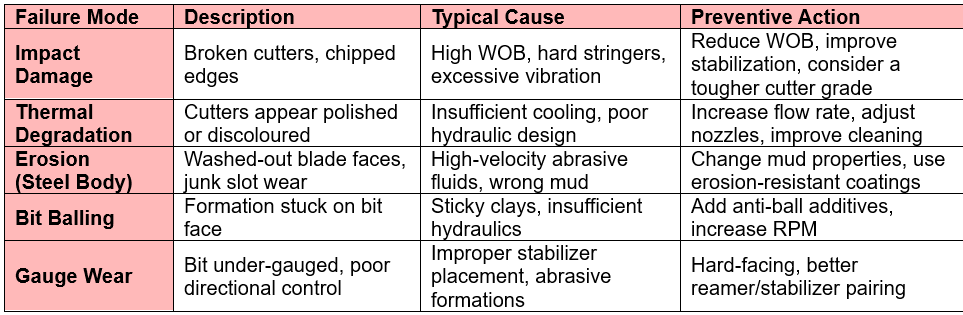

Step 3: Match the Failure Mode to the Cause

Most failures fall into a small group of predictable categories. Common PDC Bit Failure Modes & Root Causes:

Figure 3:Common PDC Bit Failure Modes & Root Causes

Figure 4:Why Your Bits Are Failing Early — And How to Fix It

Step 4: Validate Operating Parameters with Data

Most drilling dysfunction occurs not because of bit design—but because of:

- Wrong WOB

- Wrong RPM

- Poor hydraulics

- Poor stabilizer placement

- Mismatch between rig capabilities and bit needs

Recommended Workflow for Parameter Validation

- Review Surface Parameters

- Did RPM fluctuate?

- Were there torque spikes?

- Was WOB within the design limit?

- Check Pump Pressure Trends

- Sudden drop → nozzle washout

- Sudden increase → plugged junk groove / balling

- Analyse Vibrations

- Modern rigs allow real-time axial/lateral/vortex vibration monitoring.

- Cross-check with Formations Drilled

- Determine if a lithology transition occurred during failure.

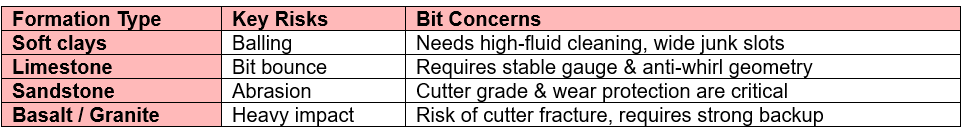

Step 5: Understand Formation Behaviour (Most Failures Start Here)

Even the best bit cannot survive if the formation conditions are misunderstood. A bit that performs brilliantly in sandstone may fail horribly in abrasive interbedded layers only meters away.

Formation-Specific Stress Factors

Figure 5: Formation-Specific Stress Factors

Step 6: Improve Bit Selection Strategy (The Most Overlooked Step)

Choosing the wrong bit is the #1 cause of premature failures—globally.

A modern selection process should consider:

- Formation hardness index

- UCS (Unconfined Compressive Strength)

- ROP expectations

- Rig horsepower & RPM limits

- Required hole cleaning velocity

- Whether directional control is needed

- Gauge protection requirements

- Expected temperature and abrasiveness

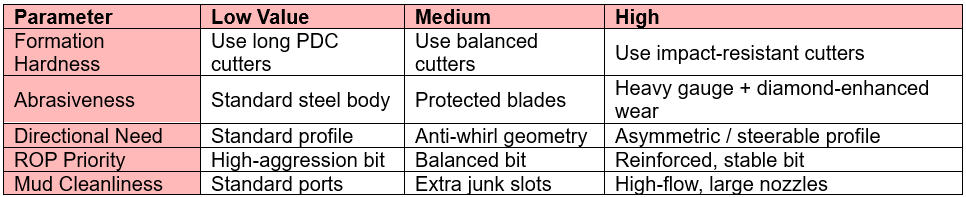

Step 7: Prevent Future Failures with a Standardised Decision Workflow

Below is a simple Decision Matrix used by many drilling teams:

Bit Selection Decision Matrix

Figure 6: Bit Selection Decision Matrix

Premature bit failure is not inevitable. It is predictable, diagnosable, and most importantly preventable but prevention depends on three pillars:

- Accurate diagnosis

- Formation-matched bit design

- Reliable manufacturing quality

This is where advanced engineering truly shows its value.

Why this matters for buyers and drilling managers

A bit is not purchased—it is invested inand the return on that investment comes from:

- Reduced trips

- Higher ROP

- Lower torque and fuel consumption

- Fewer stuck-pipe events

- Fewer reaming/smoothing passes

- Longer bit life

Companies at the forefront of drilling performance today rely on manufacturers who combine material science, cutter innovation, CFD-based hydraulic design, and field-tested geometry.

Manufacturers like Rockpecker, who engineer steel-body and matrix PDC bits for HDD, mining, geothermal, waterwell, and O&G, design tools specifically to address the exact failure modes described above. Their bits integrate optimized blade geometry, enhanced gauge protection, and CFD-validated cleaning systems—allowing operators to extend bit life even in complex formations and high-stress applications.

This makes the difference between a project that “gets by” and one that delivers predictable, optimized performance with reduced downtime.

Final Thought

Premature drill bit failure will always be a threat—but it doesn’t have to be a budget killer. By adopting a structured failure analysis approach, applying disciplined parameter control, and selecting bits engineered for your exact formation needs, drillers can dramatically extend tool life and protect their margins. Control the bit. Control the cost. Control the outcome.