How Microtunneling Tools are Paving the Way for Smart Cities

/Precision Underground: Building Tomorrow's Infrastructure Without Disrupting Today

Imagine a bustling metropolis like Tokyo, London, or New York. Beneath the vibrant streets, a hidden world of infrastructure – water pipes, sewer lines, telecommunications cables, and power conduits – forms the lifeblood of the city. As these urban centres grow, expand, and strive to become "smart" cities, the demand for new and upgraded underground utilities intensifies. However, the traditional method of open-cut trenching simply isn't feasible. The cost of disruption – traffic jams, business losses, environmental impact, and public outcry – is too high.

This is where Microtunneling emerges as an unsung hero. A sophisticated, trenchless construction method, Microtunneling allows for the installation of pipelines and conduits with remarkable accuracy and minimal surface disturbance. It's the silent revolution beneath our feet, and at its core are the specialized tools and cutting heads that make this precision possible.

Figure 1: How Microtunneling Tools are Paving the Way for Smart Cities like this 6cone Rockpecker’s Microtunneling Tool

The Challenge of Urban Infrastructure: Why Microtunneling?

The vision of a Smart City is one of seamless connectivity, efficient resource management, and enhanced quality of life. This vision relies heavily on advanced, resilient infrastructure – much of which is located underground.

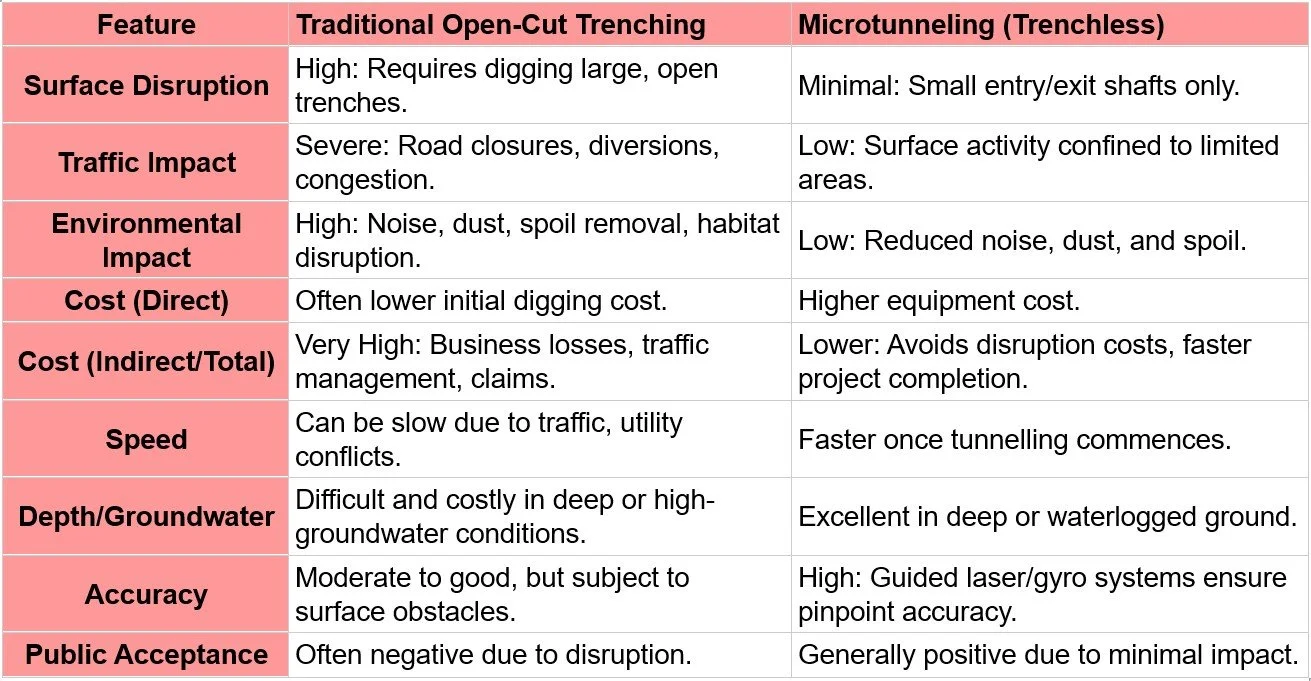

Traditional Open-Cut vs. Microtunneling in Urban Environments:

Figure 2: Traditional Open-Cut vs. Microtunneling in Urban Environments

The benefits table clearly illustrates why Microtunneling is not just a preference, but a necessity for modern urban development. It's the cornerstone of infrastructure projects that prioritize efficiency, sustainability, and quality of life.

How Microtunneling Works:

A Precision Ballet Underground Microtunneling utilizes a remote-controlled, steerable tunnelling machine (MTBM) that excavates the ground as sections of pipe are simultaneously jacked forward from a launch shaft. The process is a marvel of engineering:

- Launch Shaft: A vertical shaft is excavated to the required depth to begin the tunnel.

- Microtunnel Boring Machine (MTBM): The specialized machine, equipped with a cutting head, is lowered into the launch shaft.

- Pipe Jacking System: A powerful jacking frame pushes the MTBM forward, followed by a segment of pipe.

- Excavation & Spoil Removal: The cutting head grinds or excavates the material, which is then transported back to the launch shaft as slurry or dry spoil.

- Guidance System: Laser or gyroscopic guidance systems provide real-time data to operators, allowing for millimetric precision in steering the MTBM.

- Receiving Shaft: Once the MTBM reaches the target, it's retrieved from a receiving shaft.

The "micro" in Microtunneling refers to the fact that the machine's diameter is typically less than 3 meters, and it's always operated remotely, meaning no personnel enter the tunnel during excavation.

Roller Disc Cutters in Microtunneling

The cutting head shown uses multiple roller cutters (or disc cutters) mounted on the face of the Microtunneling boring machine (MTBM). This design is highly effective for excavating hard rock, fractured ground, or mixed-face conditions often encountered deep beneath urban areas.

- Mechanism (How it Works):

- Unlike drag bits, these cutters do not scrape the rock. Instead, they operate by crushing and fracturing the rock face.

- As the cutting head rotates, the individual hardened steel or tungsten carbide disc cutters roll across the rock face under high thrust pressure.

- This rolling action creates high stress points that cause the rock to spall (break off) into chips, which are then carried away by the slurry removal system.

- Key Role in Microtunneling:

- Hard Rock Excavation: This type of roller cutter head is essential for projects that encounter competent bedrock, which is common during deep tunnel installations.

- Durability and Longevity: Disc cutters are designed to withstand extremely high wear and tear, reducing the need for costly and time-consuming tool changes, which is a massive operational benefit in trenchless projects.

- Minimal Vibration: The rolling action minimizes vibration compared to percussive (hammer) drilling, which is vital when tunnelling beneath sensitive urban structures like high-rises or historical buildings.

The presence of this powerful roller cutter head on the advertisement highlights the company's capability to handle the most challenging underground conditions, which is a prerequisite for executing large-scale infrastructure projects like those mentioned in the preceding article on Smart Cities.

The Heart of the Operation: Specialized Microtunneling Tools The success of a Microtunneling project hinges on the performance of its cutting head and associated tools. These are not general-purpose drilling tools; they are highly specialized instruments designed to:

- Excavate Diverse Geologies: From soft clays and sands to hard rock and mixed ground conditions.

- Maintain Face Stability: Prevent collapses in challenging ground.

- Navigate Obstacles: Cut through boulders, old foundations, and even unrecorded utilities.

- Ensure Accuracy: Work in conjunction with the guidance system to maintain the precise line and grade of the tunnel.

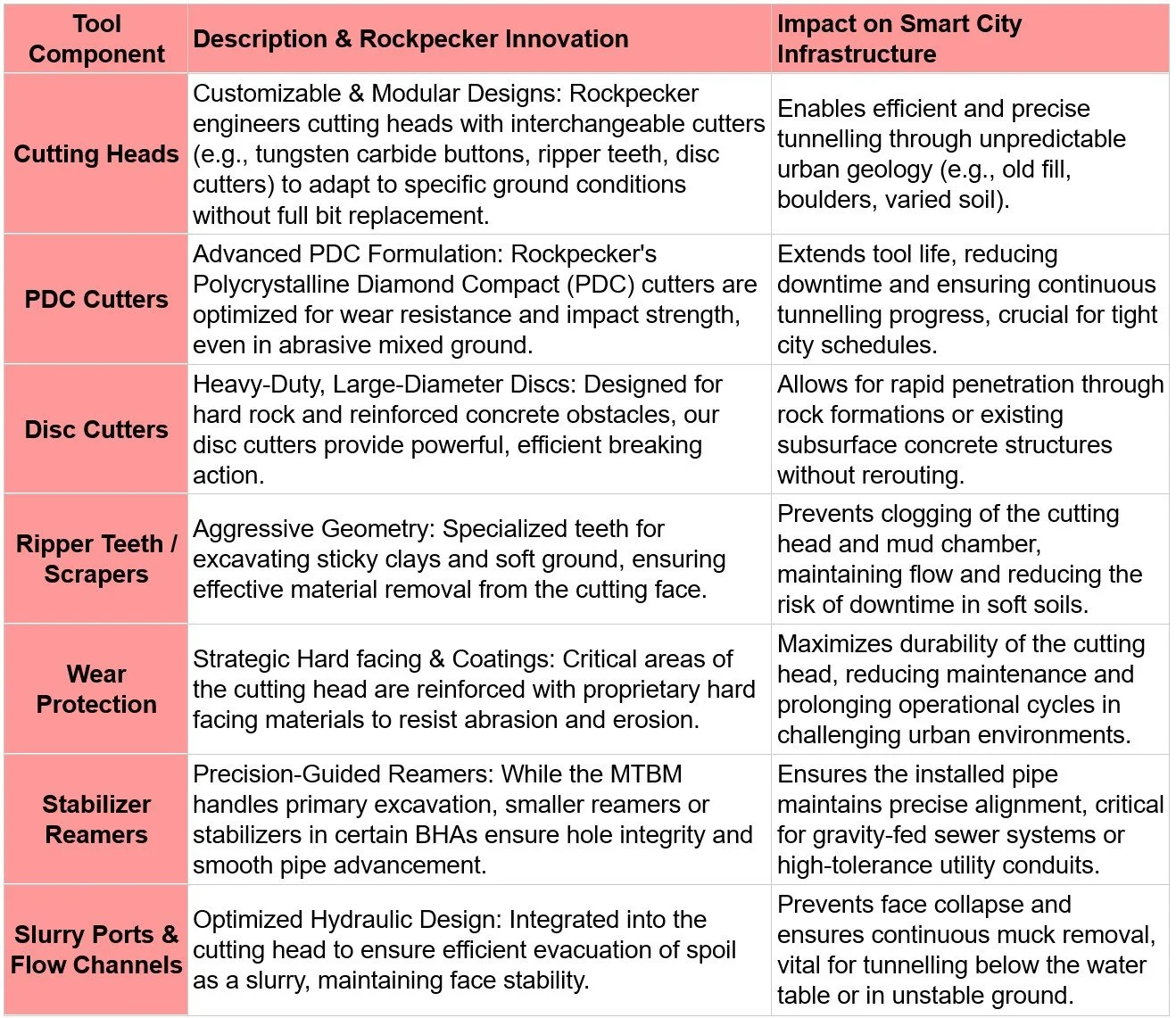

Figure 3: Another successful Microtunneling Tool Rockpecker Georgy

Key Tooling Innovations from Rockpecker for Microtunneling:

Figure 4: Key Tooling Innovations from Rockpecker for Microtunneling

Microtunneling: Paving the Way for Smart City Connectivity

Smart Cities depend on interconnected networks that transcend the surface. Microtunneling provides the conduit for this connectivity without disrupting the delicate balance of urban life.

- Fiber Optic Networks: Installing high-capacity fibre optic cables for widespread IoT (Internet of Things) deployment, 5G connectivity, and smart grids.

- Water & Wastewater Modernization: Replacing aging, leaking pipes or installing new, larger capacity lines to support growing populations and prevent environmental contamination.

- Energy & Utility Distribution: Safely routing gas lines, electrical conduits, and district heating/cooling pipes through densely populated areas.

- Stormwater Management: Building resilience against climate change by installing large-diameter stormwater tunnels to prevent urban flooding.

Each of these applications directly contributes to the core pillars of a Smart City: efficiency, sustainability, and enhanced public services.

Conclusion:

The Unseen Foundation of Tomorrow's Cities The urban revolution towards smarter, more sustainable cities is intrinsically linked to advancements in trenchless technology, particularly Microtunneling. As cities worldwide face the dual challenge of aging infrastructure and rapid expansion, the ability to build and upgrade essential utilities with minimal disruption becomes paramount.

Rockpecker's specialized cutting heads and Microtunneling tools are not just components; they are engineered solutions that empower contractors and civil engineers to overcome the most complex underground challenges. Our commitment to precision, durability, and adaptability ensures that the unseen foundations of smart cities are built to last. By consistently delivering cutting-edge tooling for demanding urban environments, Rockpecker remains a trusted partner in shaping the future beneath our feet.