Bi-Center PDC Bits A Smarter Approach to Hole Enlargement in a Single Run

/In the demanding world of earth drilling applications, achieving optimal wellbore geometry is paramount for efficient production and long-term well integrity. Traditional drilling methods often involve multiple trips downhole to enlarge the wellbore, adding time, cost, and inherent risks. Enter the Bi-Center Bit, an innovative drilling tool designed to streamline this process by enabling seamless expansion and providing superior control, all while maximizing the wellbore diameter and minimizing potential complications.

What is a Bi-Center PDC Bit?

A Bi-Center Bit is a hybrid drilling tool engineered with two concentric cutting diameters & Centers:

- A pilot section that drills the initial hole.

- A reaming section offset slightly from the pilot, immediately follows and enlarges the borehole to the desired/ final diameter in a single pass. This unique design eliminates the need for a dedicated reaming run, offering significant advantages in terms of operational efficiency and reduced non-productive time.

Figure 1:Bi-Center PDC Bits: A Smarter Approach to Hole Enlargement in a Single Run

Key Design Elements

1. Steel or Matrix Body Construction: Most Bi-Center bits used today are built on steel-body PDC designs, offering high durability, precision machining, and strong cutter retention.

2. Pilot Section:

- Responsible for initiating the borehole and maintaining directional control.

- Typically sized smaller than the final required hole.

3. Reamer Section:

- Strategically offset from the pilot and equipped with a secondary ring of PDC cutters.

- Enlarges the wellbore as it follows the pilot.

- Designed with hydraulic nozzles to ensure effective cuttings evacuation.

4. Optimized Hydraulics: Fluid flow paths are engineered to manage cuttings transport across both cutting sections, reducing balling and ensuring smooth enlargement.

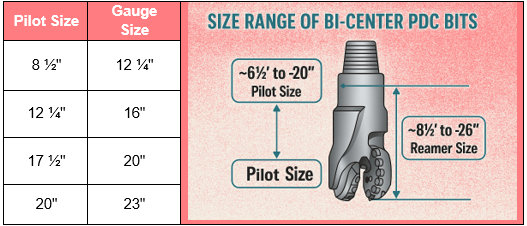

Size range of Bi-Center PDC Bits

Size generally depends on two key dimensions: 1. Pilot Bit Size – the smaller diameter section that passes through restrictions like casing. 2. Reamer (Gauge) Size – the larger diameter section that enlarges the hole while drilling.

Typical Size Ranges

- Pilot Hole Sizes: 6 ½" to 20" (165 mm to 508 mm)

- Enlarged Hole Sizes (Gauge): 8 ½" to 26" (216 mm to 660 mm)

The reamer diameter is usually 1–3 inches larger than the pilot bit, but in some cases (especially offshore or large conductor hole applications), the difference can be more substantial — up to 5–6 inches.

Example Configurations:

Figure 2: Size range of Bi-Center PDC Bits.

These are just typical examples. Sizes can be custom-designed depending on:

- Formation conditions

- Casing/liner sizes

- Hole enlargement requirements

- Rig specifications

The Mechanics of Seamless Expansion

The key to the Bi-Center Bit's effectiveness lies in its carefully engineered geometry and the dynamic interaction between its two cutting Centers. As the bit rotates and advances, the pilot section establishes the initial trajectory and gauge. The trailing reamer section, with its larger diameter and strategically placed cutters, then engages the newly drilled formation, smoothly and efficiently enlarging the wellbore.

This simultaneous drilling and reaming action ensure a consistent and high-quality enlarged borehole. The gradual expansion minimizes the risk of ledges or irregularities that can occur with separate reaming runs, leading to smoother casing installation and improved cementation.

Bi-Center PDC bits are used to deepen wellbores. They feature a front pilot section and a rear reamer section. Their size is denoted as XX" x XX", where the first number represents the running diameter (the size when entering the hole) and the second represents the rotating diameter (the enlarged hole size).

For instance, a 4 ½" x 5 ½" bit has a 4 ½" diameter when going into the well, and it creates a 5 ½" diameter hole when drilling and reciprocating.

How It Works: Tripping vs. Drilling A critical feature of Bi-Center Bits is their ability to trip through the casing without compromising hole diameter during drilling.

- Tripping In: The bit is sized to pass through a smaller casing restriction (e.g., 20-inch casing).

- While Drilling: Once the bit is past the restriction, it enlarges the hole (e.g., up to 23 inches) due to the reamer section's offset geometry. This dynamic is visualized in the figure showing how the pilot bit section aligns during tripping, while the reamer takes over during active drilling to enlarge the hole.

Figure 3: How Bi-Center PDC Bit works: Tripping vs. Drilling

Superior Control- Navigating Complex Well Paths

Beyond efficient enlargement, Bi-Center Bits offer enhanced directional control, particularly crucial in complex well trajectories. The pilot section acts as a stabilizer, maintaining the intended well path while the reamer section expands the diameter. This inherent stability reduces the tendency for the bit to wander or deviate, leading to more accurate wellbore placement and minimizing the risk of costly sidetracks.

Furthermore, advancements in Bi-Center Bit technology have incorporated features such as steerable designs, allowing operators to actively adjust the bit's trajectory while drilling and enlarging the wellbore simultaneously. This capability is invaluable in navigating challenging geological formations and achieving precise wellbore placement in directional and horizontal wells.

Benefits of Using Bi-Center PDC Bits

Figure 4: Benefits of Using Bi-Center PDC Bits

Applications and Advancements

Bi-Center Bits have found widespread application across various drilling scenarios, including:

- Conventional vertical wells: Enhancing drilling efficiency and ensuring optimal hole quality for casing installation.

- Directional and horizontal wells: Providing superior control and enabling efficient enlargement in complex well paths.

- Underreaming applications: Some Bi-Center Bit designs can be deployed to underream specific sections of the wellbore for specialized purposes.

- Casing drilling: Specialized Bi-Center Bits are being developed and utilized to drill and simultaneously case the wellbore, offering even greater time and cost savings.

Ongoing advancements in materials science, cutting structure design, and hydraulics are further enhancing the performance and versatility of Bi-Center Bits. Innovations such as improved cutter technology for increased rate of penetration and longer bit life, as well as optimized fluid flow for efficient cuttings removal, are continually expanding the capabilities of these valuable drilling tools.

Limitations to Consider

While highly effective, Bi-Center PDC Bits may not be ideal in:

- Highly abrasive or interbedded formations where wear rates are unpredictable.

- Wells requiring extremely precise gauge control where a single-diameter bit is preferred.

Recent Advancements

With improvements in:

• Cutter durability (thermal stability, impact resistance) • Hydraulics optimization • Bit design using 3D modelling and FEA simulations. • Modern Bi-Center PDC bits are pushing boundaries of rate of penetration (ROP), borehole stability, and tool longevity.

Conclusion

The Bi-Center Bit represents a significant step forward in drilling technology, offering a compelling solution for efficient and controlled wellbore enlargement. By seamlessly integrating drilling and reaming into a single operation, these bits maximize wellbore diameter, minimize operational risks, and contribute to more cost-effective and productive drilling campaigns. As the industry continues to seek innovative solutions for optimizing drilling performance, the Bi-Center Bit will undoubtedly remain a crucial tool in unlocking the full potential of subsurface resources.