A Budget-Conscious Approach for Transitioning from 6.5" Pilot Hole to 42" PDC Reamer

/Every driller and project manager knows the daily grind of budgeting under pressure—stretching limited resources while being expected to deliver precision under punishing timelines.

The juggling act often begins long before a bit hits the ground: choosing the right tools that offer both reliability and long-term cost savings.

You’re staring at the numbers, wondering whether to risk another rebuilds or finally try something new that promises fewer delays and more uptime.

It’s a reality we’ve all faced—making tooling decisions that could mean the difference between hitting targets or burning through the budget.

This article speaks directly to that experience, offering a step-by-step strategy to ream from a modest 6.5" pilot hole to a 42" bore using Rockpecker’s field-proven PDC reamers. If you’ve ever questioned whether premium tooling is worth the upfront investment—read on.

- Project Overview Objective: Enlarge a 6.5" pilot hole to a 42" diameter bore using a staged PDC reaming strategy.

- Application: Applicable to Horizontal Directional Drilling (HDD), mining operations, large-diameter utilities, and major infrastructure installations.

- Challenges: Managing aggressive diameter expansion, torque loads, tool stability, borehole integrity, and efficient cuttings removal.

This article outlines a practical, field-validated, and cost-conscious approach to using Polycrystalline Diamond Compact (PDC) reamers to achieve a final 42" bore diameter starting from a 6.5" pilot hole. The focus is on staged reaming, tooling strategy, cost comparison, and engineering feasibility.

- Determining the Optimal Pilot Hole Size and Reaming Strategy While a 6.5" pilot hole is a common starting point for directional drilling, expanding it directly to 42" is technically impractical. A staged reaming strategy significantly reduces stress on both the tooling and the rig, maintaining borehole quality and reducing risk.

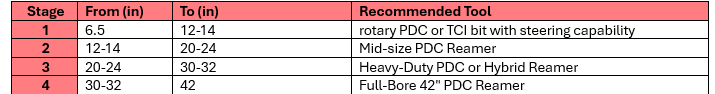

Recommended Multi-Stage Reaming Strategy:

This progression balances torque, cuttings load, and drilling fluid dynamics, avoiding excessive tool wear or borehole deviation.

- Technical Feasibility

- Rig Requirements

- Pullback capacity: ≥100,000 lbs

- Torque capacity: ≥40,000 Nm

- Mud flow: High-capacity pumps with adequate solids control.

- Tool Selection

- PDC Reamers: Rockpecker’s PDC reamers feature balanced cutter layout, optimized flow paths, and wear-resistant materials tailored for multistage reaming.

- Stabilizers: Recommended above and below the reamer to ensure centralization and bore accuracy.

- Drill Pipe & Joints: Must withstand bending and axial loads during large-diameter reaming.

- Operational Parameters

- Mud Management: Essential for transporting larger cuttings and cooling down the reamer.

- Steering Accuracy: Must be ensured from pilot stage; post-24" reaming provides minimal trajectory control.

- Bore Cleaning Passes: Recommended after each stage to clear debris and maintain path quality.

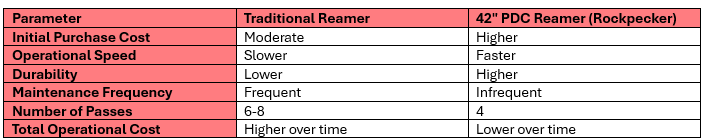

- Cost Comparison: Traditional vs. PDC Reaming

Estimated Cost Savings & Outcomes:

- Drilling Time Reduction: 35% decrease in operational hours

- Overall Cost Reduction: 30% savings in labour, fuel, and maintenance

- Tool Longevity: Rockpecker’s PDC reamers retained 80-90% of usable cutters after project completion

- Practical Feasibility: Stabilizers and Tool Path Control In large-diameter reaming, stabilizers become critical:

- Above and below the reamer: Maintain alignment and reduce vibration.

- Cuttings Distribution: Help evenly distribute forces and prevent tool deviation.

- Extended Tool Life: Reduced off-centre loading prevents premature cutter damage. This is especially important when passing through mixed ground conditions or hard rock layers.

- Execution Workflow: Step-by-Step Guide Step 1: Drill 6.5" Pilot Hole

- Use rotary PDC or TCI bit with steering capability

- Maintain bore accuracy; this determines success of all subsequent stages Step 2: Stage 1 Ream (6.5" → 12-14")

- Use a small fly cutter or compact Rockpecker PDC reamer

- Monitor torque closely and ensure good fluid circulation Step 3: Stage 2 Ream (12-14" → 20-24")

- Mid-size Rockpecker PDC reamer with 4-6 blades

- Introduce stabilizers, clean borehole periodically Step 4: Stage 3 Ream (20-24" → 30-32")

- Use robust Rockpecker reamer with large cutters and high flow rates

- Monitor pullback and increase mud additives for better suspension Step 5: Final Ream (30-32" → 42")

- Deploy 42" Rockpecker PDC reamer with maximum stabilization

- Adjust rig pullback speed for consistency and bore wall integrity Step 6: Final Bore Cleaning & Survey

- Conduct swabbing or light passes

- Borehole camera or calliper log for QA/QC

- Conclusion Reaming from a 6.5" pilot hole to a 42" final bore using PDC technology is both practical and cost-efficient when done using a structured, staged approach. Key success factors include:

- Selecting correct tool sizes and transitions

- Ensuring equipment compatibility

- Managing drilling fluids and borehole cleaning Operators following this method benefit from:

- Fewer tool replacements

- Shorter project timelines

- Lower overall costs At Rockpecker, we don’t just supply reamers—we deliver performance, field-tested engineering, and solutions that add value from the first cut to the last pass. If you’re looking to ream smarter, faster, and with more confidence, reach out to Rockpecker today and equip your next project with tools designed to go the distance.