Canada and Australia’s Growing Influence in Trenchless Innovation

/A New Global Shift in Subsurface Engineering

Trenchless technologies have evolved from specialized techniques into mainstream solutions for modernizing underground infrastructure. Among the countries advancing this shift, Canada and Australia are setting strong examples through their technological adaptations, large-scale deployment, and sustainability focus. Whether it’s Microtunneling through glacial terrains in Canada or horizontal directional drilling (HDD) across arid and rocky zones in Australia, these nations continue to demonstrate versatility and leadership in subsurface development.

With rising urbanization, aging utility systems, and increasing environmental considerations, both countries are embracing trenchless techniques not only for their efficiency but as long-term, resilient strategies. This article explores how these two regions are helping shape the global trenchless landscape through innovation, practical execution and regional leadership with Rockpecker supporting contractors in both markets.

Figure 1: Canada and Australia’s Growing Influence in Trenchless Innovation

1. Canada- Engineering Excellence Meets Environmental Consciousness:

Canada's trenchless market is being driven by urgent infrastructure needs and stringent environmental regulations. Key cities like Toronto, Vancouver and Calgary are heavily investing in water, wastewater and fibre optic installations using trenchless methods. Canada's extreme climate and glaciated soil profiles present unique technical challenges, prompting the use of advanced HDD rigs, gyro-guided navigation systems and tailored reamer solutions.

- In Canadian regions, CIPP (Cured-in-Place Pipe) is the predominant rehabilitation method, particularly for water infrastructure, with usage described as “far more widespread” than in the U.S.

- HDD remains the primary technique for new underground installations, especially in line with sewer force mains and telecom conduit laying.

- Growth drivers include cold weather limitations on open-cut, environmental concerns and municipalities exploring less disruptive methods

Government support has also been pivotal. Municipalities are encouraged to use trenchless methods through grant-funded programs aimed at minimizing environmental impact and community disruption. Canada’s commitment to reducing greenhouse gas emissions aligns well with the low-carbon footprint of trenchless technologies.

A major municipal infrastructure upgrade in Southern Ontario leveraged pipe bursting and horizontal directional drilling (HDD) to modernize aging sewer systems while minimizing disruption to nearby ecosystems.

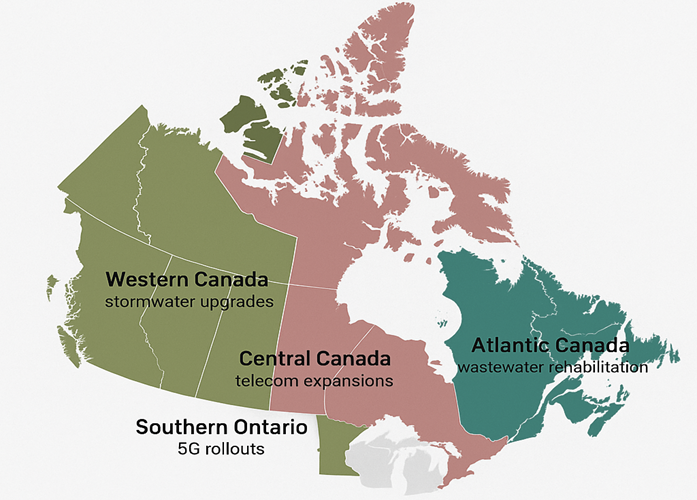

Figure 2:Map of Canada highlighting major trenchless hotspots with brief project tags (e.g., Toronto: 5G rollouts, Calgary: stormwater rehab).

Rockpecker Canada Inc., in Ontario, supports trenchless contractors across North America with advanced reamers and HDD tooling customized for challenging glacial and mixed ground formations.

2. Australia- Resilience in Harsh Ground Conditions:

Australia presents a contrasting yet equally demanding trenchless landscape. From the rocky terrain of Western Australia to the congested underground networks of Sydney and Melbourne, Australian contractors have become adept at drilling through abrasive soils, high-temperature zones and dense urban corridors.

- Trenchless practices are growing both in urban utility networks and mining corridors. The sector is fuelled by environmental mandates and a need to maintain infrastructure with minimal ecological disturbance.

- Approximately 38% of water pipeline rehabilitation contracts in Australia now use trenchless methods, significantly higher than in regions without regulatory incentives.

A major contributor to trenchless growth in Australia is its mining and energy sectors. These industries often require advanced borehole drilling for pipeline installation across remote areas. Additionally, Australia has shown leadership in integrating trenchless solutions into renewable energy infrastructure, such as using HDD to install cables for solar farms and wind power transmission.

Australia also benefits from strong collaboration between academia, government and private industry. Institutions like the University of Queensland conduct ongoing research on trenchless equipment performance and geotechnical modelling.

Rockpecker Australia Pty. Ltd., based in Perth, provides rugged downhole tools and design support for HDD and mining-related trenchless applications throughout Australasia.

3. Innovation in Materials and Methods:

Both countries have been quick to adopt and refine advanced downhole tooling, materials and control systems. Canadian companies are piloting autonomous guidance systems and low-impact drilling fluids, while Australian firms are innovating with PDC cutter designs to improve tool life in mixed formations. Key Areas of Innovation:

- Smart Tracking: Real-time telemetry in HDD navigation.

- Eco-Drilling Fluids: Environmentally safe polymers and additives.

- Reamer Designs: Wear-resistant materials for high-torque bores.

- Digital Planning: GIS integration and 3D bore path modelling.

These innovations are not just localized Canadian and Australian companies are exporting both technology and talent globally. Their tools and methods are increasingly being adopted in Southeast Asia, the U.S. and parts of Europe.

Figure 3:comparing adoption rates of different trenchless methods (HDD, pipe bursting, CIPP, Microtunneling) in Canada vs. Australia from 2018 to 2024

4. Workforce and Training Leadership: The success of trenchless projects depends not just on technology but also on skilled operators and planners. Canada and Australia are investing heavily in workforce development.

In Canada, programs through CATT (Centre for Advancement of Trenchless Technologies) and NASTT Canada provide certification and continuing education for contractors and engineers. Similarly, Australia's ASTT (Australasian Society for Trenchless Technology) offers training that focuses on safety, environmental standards and method selection.

Both countries are also embracing digital training simulators and VR environments to prepare crews for real-world trenchless scenarios without physical risk.

5. International Influence and Export Potential: As global infrastructure challenges mount, Canadian and Australian trenchless companies are stepping onto the international stage. Australian HDD service providers are active across Southeast Asia and the Middle East, while Canadian manufacturers are exporting reamers, mud motors and guidance systems to North America and Europe.

Trenchless knowledge sharing is also expanding. Both countries host major trenchless conferences and have contributed to global standards on safety, material use and design. With active participation in the International Society for Trenchless Technology (ISTT), their influence continues to grow.

Conclusion:

Despite the distance, Canada and Australia are connected by their shared dedication to trenchless innovation, driving ground-level progress with global impact. Their ability to adapt to extreme conditions, invest in sustainable solutions and foster talent makes them global leaders in this field.

In Canada, CIPP dominates pipeline rehabilitation, especially in colder regions where excavation is costly and disruptive. For new installations, like telecom or water crossings, HDD remains the go-to method.

In Australia, nearly 40% of water infrastructure rehabilitation contracts now rely on trenchless techniques, driven by regulatory sustainability requirements and the need to protect sensitive landscapes around mining zones and urban areas.

As the world moves toward smarter cities and resilient infrastructure, the trenchless solutions pioneered and perfected in Canada and Australia will be crucial. With each successful project, they not only solve local problems but also pave the way for global best practices in underground construction.

With operational bases in Ontario ( Rockpecker Canada Inc.) and Perth ( Rockpecker Australia Pty. Ltd.), Rockpecker is proud to support the growth of trenchless innovation across both regions. Our advanced downhole tools, local design support and deep industry insight help contractors drill smarter, safer and more efficiently.