From Rock to Reservoir: The Critical Tools That Drill the World's Wells

/Drilling for oil and natural gas is a multi-stage process that relies heavily on precision, durability, and advanced downhole drilling tools. From the first surface hole drilled into the ground to the final completion phase where hydrocarbons are extracted, each stage requires specific tools with different sizes, functions, and designs to deliver efficiency, safety, and productivity.

Among these, PDC (Polycrystalline Diamond Compact) bits have revolutionized drilling by providing speed, durability, and the ability to cut through various rock formations. Yet, they are only one part of a larger system of reamers, stabilizers, hole openers, casing tools, and completion equipment that work in sequence.

Figure 1: From Rock to Reservoir: The Critical Tools That Drill the World's Wells

Below, we break down the drilling workflow, tool-by-tool and stage-by-stage, to explain how hydrocarbons are brought from deep within the Earth to the surface.

Stage 1: Site Preparation & Spudding The drilling process begins with site preparation: levelling ground, setting up the rig, and preparing the well pad. Once ready, drilling starts with a spud bit.

Tools used:

- Spud Bits (roller cone or small PDC, sizes 8 ½”–12 ¼”) – cut through unconsolidated surface formations.

- Stabilizers (8”–12”) – keep the borehole aligned and minimize deviation.

The goal is to drill through soft formations until reaching competent rock for casing.

Stage 2: Surface Hole Drilling The surface casing hole ensures stability and prevents collapse of loose formations. Large bits create wide boreholes to house the first casing string.

Tools used:

- Large Diameter PDC or Tricone Bits (17 ½”–26”) – drill shallow, large-diameter sections.

- Hole Openers/Reamers (roller cone or PDC, up to 36”) – enlarge boreholes for casing.

- Near-bit Stabilizers – placed close to the bit for trajectory control.

- Casing Shoes – attached to 20”–22” casing to guide it into place.

After drilling, the surface casing is cemented to protect groundwater and secure the well.

Stage 3: Intermediate Hole Drilling The intermediate section extends deeper into the subsurface, often through unstable shales or over-pressured formations.

Tools used:

- PDC Bits (12 ¼”–14 ¾”) – durable and efficient across mixed lithologies.

- Reamers / Hole Openers (10”–16”) – enlarge pilot holes for casing.

- Stabilizers & Drill Collars – provide weight on bit, reduce vibration, and maintain trajectory.

- Underreamers (14”–18”) – expand the borehole below casing points. This stage sets the foundation for accessing the reservoir.

Stage 4: Production Hole Drilling This phase targets the reservoir itself. Accuracy is critical to maximize hydrocarbon recovery.

Tools used:

- PDC Bits (6”–8 ½”) – fast, durable cutters for reservoir penetration.

- Hybrid Bits (PDC + roller cone, 6 ½”–9”) – handle abrasive or interbedded formations.

- Stabilizers (6”–8”) – reduce vibration and protect tools.

- Bi-Center Bits – allow drilling and enlarging simultaneously.

- Rotary Steerable Systems (RSS) – enable precise directional drilling with integrated PDC bits.

Advanced tools like MWD (Measurement While Drilling) and LWD (Logging While Drilling) guide the bit into the productive zone.

Stage 5: Well Enlargement & Hole Conditioning Before casing and completion, the borehole may need conditioning to smooth ledges and allow casing to pass freely.

Tools used:

- Reamers (8 ½”–18”) – maintain hole gauge and enlarge to match casing design.

- Near-Bit Reamers – mounted close to the PDC bit for simultaneous drilling and reaming.

- Stabilizers – reduce spiralling and ensure smooth boreholes.

- Underreamers – expand the hole beneath casing shoes.

Stage 6: Casing & Cementing Once drilled, the borehole is secured with steel casing strings and cement to prevent fluid migration and isolate zones.

Tools used:

- Casing Shoes & Float Collars (9⅝”–13⅜”) – guide casing into place.

- Cementing Plugs – separate cement slurry and fluids.

- Reamer Shoes (10”–14”) – ease casing through tight spots.

- Centralizers – keep casing cantered for even cement distribution. Proper casing and cementing ensure long-term well integrity and environmental protection.

Stage 7: Well Completion Completion transforms the drilled well into a producing asset by creating controlled flow paths for hydrocarbons. Tools used:

- Completion Bits (4 ¾”–6 ½”) – for final cleanout.

- Perforating Guns – fire charges through casing and cement into the reservoir.

- Liner Hangers & Packers – isolate zones and support production equipment.

- Expandable Reamers – enlarge sections if needed for liners.

Stage 8: Hydrocarbon Flow Finally, hydrocarbons are moved from the reservoir to the surface through dedicated tubing. Tools used:

- Production Tubing (3½”–5½”) – provides a stable flow path.

- Artificial Lift Systems – boost production when reservoir pressure declines:

- Rod Pumps (Beam Pumps) – for shallow to medium wells.

- Gas Lift Valves – inject gas to lighten the hydrocarbon column.

- Electric Submersible Pumps (ESP) – move large volumes from deep wells.

Why Sizes Matter The choice of tool sizes directly affects drilling efficiency, casing design, and production rates. A typical well may begin with a 26” surface hole, transition to 12¼” intermediate holes, and finish with 8½” production holes before installing 3½”–5½” tubing. Each reduction balances safety, geology, and cost.

Why PDC Bits Dominate Modern Drilling PDC bits have become the industry’s workhorse because they:

- Offer superior cutting efficiency compared to roller cones.

- Cover all hole sections with sizes ranging from 3 ⅞” to 26”.

- Reduce trips and downtime, cutting rig costs.

- Perform across a wide spectrum of rock types.

While PDC bits dominate, performance is enhanced by reamers, stabilizers, and directional drilling assemblies that ensure smooth, in-gauge boreholes and precise placement.

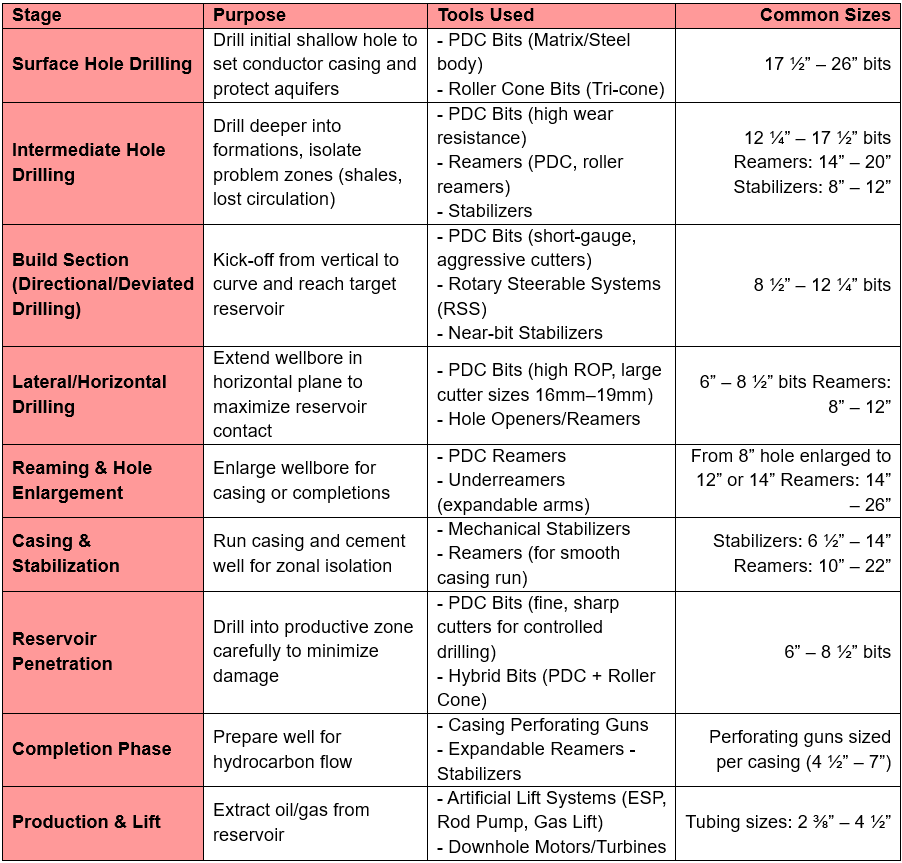

Figure 2: Minerals, Oil & Gas Extraction Process at a Glance – Stages, Tools & Sizes

Conclusion Minerls, Oil and gas extraction is not just drilling a hole — it is a precision-engineered sequence of stages where every tool has a specific role. From massive 36” hole openers at the surface to finely tuned 6” PDC bits in the reservoir, tool selection is critical to success. From the first cut at the surface to hydrocarbons flowing through 3½” production tubing, downhole drilling tools enable the safe and efficient delivery of energy. PDC bits provide speed and durability, while reamers, stabilizers, casing equipment, perforating systems, and lift tools ensure a smooth transition from drilling to production. Together, they form the invisible chain that brings hydrocarbons from deep beneath the Earth to the surface — powering industries and societies worldwide.