Low-Footprint Drilling: Tool Choices That Cut Water, Mud & CO₂

/An ESG-focused guide — how bit selection, reamer geometry and hydraulics reduce mud/circulation volumes, cuttings, and overall emissions.

As the energy, water, and infrastructure sectors tighten ESG requirements, project owners and municipal specifiers are asking a new question: can we drill smarter, so the environment isn’t the casualty of progress? The short answer is yes.

The right downhole tools, thoughtfully selected PDC and TCI bits, optimized reamers and hydraulically efficient nozzle layouts, materially reduce water and mud usage, cuttings volumes, truck movements, rig time, and ultimately CO2 emissions. At Rockpecker, we believe that the most impactful changes often begin at the fundamental interface of the tool and the rock. This article explains how, why it matters, and what practical steps teams can take to shrink their drilling footprint without sacrificing performance or budgets.

Figure 1:Footprint Drilling: Tool Choices That Cut Water, Mud & CO₂

Why tooling matters for ESG Drilling operations are resource-intensive: large fluid volumes for cooling and cuttings transport, heavy fuel consumption for rigs and support vehicles, and waste (cuttings + used fluids) that must be treated or disposed. Regulators and financiers now factor environmental intensity into permitting and cost of capital. For municipal projects, community tolerance for disruption is low and scrutiny is high. So, every litre of fluid saved, every reduction in trips and hole time, and every tonne of CO2 avoided strengthens a project’s permitability, public acceptance, and bottom line.

Tooling is a high-leverage place to act because it sits at the interface of rock, fluid, and rig. Smart tool choices change the physics of drilling: improve Rate of Penetration (ROP), reduce re-runs, improve hole cleaning, and require less pumped volume for the same performance.

How Tools Reduce Water, Mud and Emissions: The Technical Levers

1. Bit selection: match cutter tech to the formation

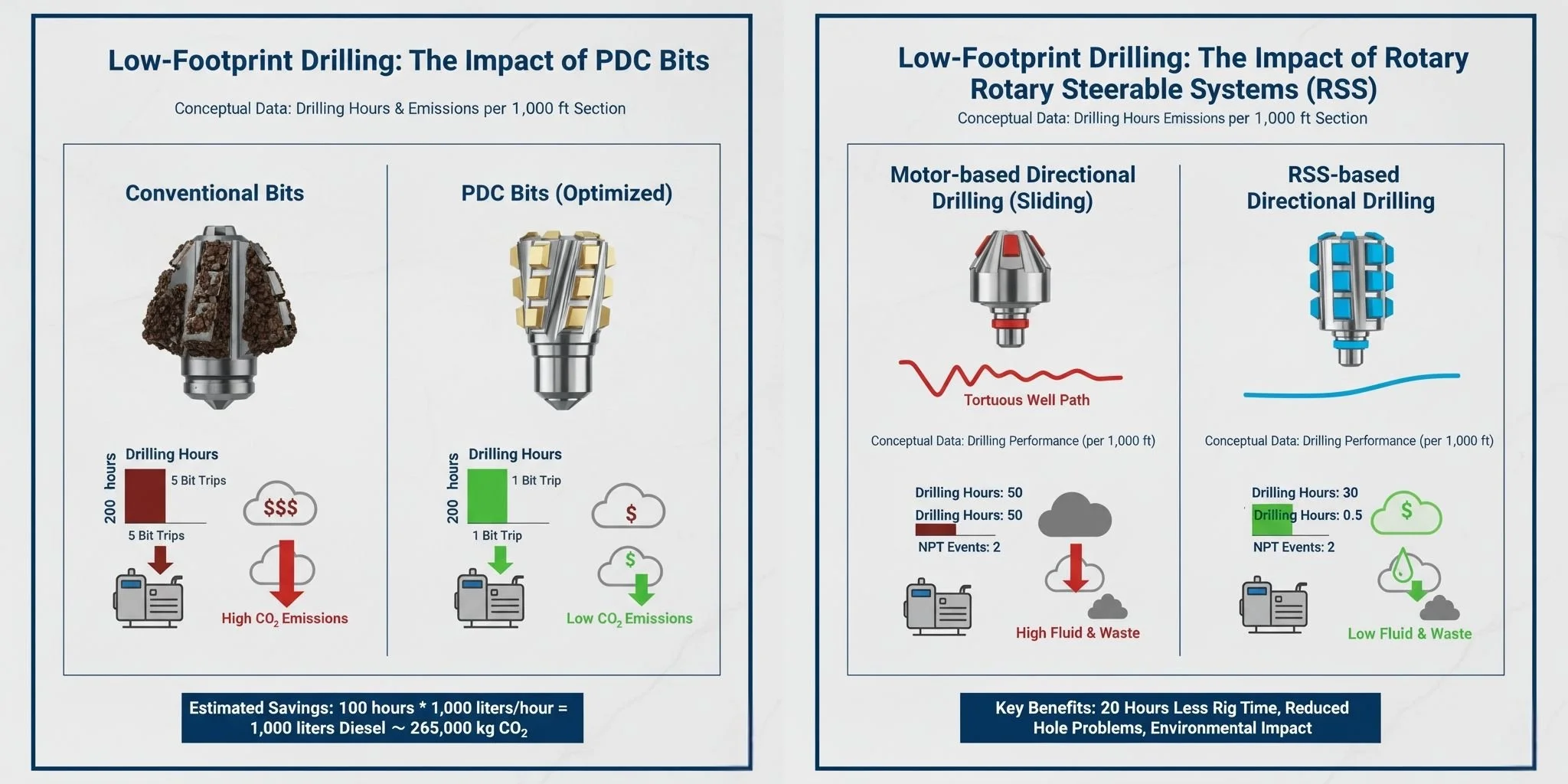

- PDC bits are at the forefront of drilling efficiency. Unlike roller cone bits that crush and gouge rock, PDC bits use fixed cutters with synthetic diamond layers to shear rock. This shearing action, when optimized, results in significantly higher rates of penetration (ROP) and extended bit life.

PDC bits (properly configured) often deliver higher ROP and longer life in consistent, abrasive formations. Higher ROP = fewer hours on bit and less circulating time.

TCI bits remain ideal in highly fractured or variable hard formations where impact resistance matters. Selecting the correct cutter material avoids premature failure and extra trips.

Cutter geometry and placement (3D cutters, staggered layouts) improve cutting removal efficiency and reduce regrinding of rock so less circulation needed to clear the face.

Practical effect: A well-matched bit can reduce circulating time by 10–30% compared to an off-the-shelf, poorly matched bit — directly reducing pumped fluid volumes and fuel used by the rig.

2. Reamer geometry and aggressive but clean hole enlargement Fluted reamers and flycutters with optimized flute geometry evacuate cuttings more effectively. Better evacuation means less recirculation and lower risk of balling (which otherwise requires extra fluid and trips).

Correct reamer aggressiveness avoids overcutting (which increases cuttings volume) while still delivering target gauge.

Practical effect: Right-sized reaming reduces cuttings mass to be handled at surface and shortens hole conditioning time after reaming. `

3. Hydraulics: nozzle sizing, placement and pressure drop at the bit Optimized nozzle sizing and oriented jets create a pressure drop at the bit face that helps shear cuttings into transportable sizes and suspends them in the flow.

Targeted center-flush or max-flush designs move cleaning power where it matters and reduce the need for total pumped volume.

Hydraulic efficiency reduces required pump horsepower and thus diesel consumption.

Practical effect: Thoughtful hydraulic design can lower pumped volumes by 15–40% for given hole sizes and formations, directly lowering water use, mud additive needs, and fuel for circulation pumps.

4. Fewer trips = lower footprint Every pipe trip (connection, make-up, run) burns fuel for rig engines, support vehicles, and logistics. Tools that extend life and achieve goals in a single pass (e.g., bi-center bits for certain applications or integrated reamers) cut trips and emissions-substantially.

Practical effect: Reducing just one trip per well can translate into measurable fuel savings and fewer site disturbances. `

Economic & regulatory drivers that favour low-footprint tooling

Permitting: Municipal authorities and environmental agencies increasingly require mitigation plans for fluid use and cuttings disposal. Demonstrating a low-footprint tooling approach eases approvals.

Cost of disposal: Treating and transporting cuttings and used drilling fluids is expensive; reducing volumes yields direct OPEX savings.

Carbon accounting & procurement: Many operators and financiers require carbon disclosure; lower scope-1/2 emissions from faster jobs and lower pump fuel consumption improve company metrics and may reduce financing costs.

Community relations: Shorter jobs and fewer truck movements improve local acceptance and reduce opportunities for project delays.

Case ROI snapshot (illustrative)

Figure 2: Case ROI snapshot (illustrative)

Practical checklist for low-footprint drilling (for project owners & specifiers)

1. Project planning

- Gather accurate formation logs or nearby well data.

- Define fluid constraints (water availability, disposal limits).

- Set ESG targets (max water used, CO2 per meter, max trips).

2. Tool selection

- Choose bit type by formation (PDC for consistent abrasive / TCI for variable hard).

- Specify cutter geometry optimized for cuttings size and ROP (consider 3D cutters for difficult abrasives).

- Select reamer/fluted geometry to balance gauge and evacuation.

3. Hydraulics & circulation

- Use nozzle maps tailored to bit/reamer; prefer center or max-flush where balling risk exists.

- Model pressure drops at bit to ensure efficient shearing and transport.

- Size pumps for efficient operation, not brute force, match flow to hydraulic design.

4. Operational best practice

- Establish ROP / WOB / RPM “sweet spot” in initial footage; avoid “out-drilling” the bit.

- Monitor torque, surface pressure and standpipe; tune flow to avoid over-pumping.

- Minimize trips by using single-run solutions where applicable.

5. Measure & report

- Track pumped volumes, fuel burn, trips, and waste volumes per well.

- Report CO2 intensity per meter drilled and water usage to internal ESG dashboards.

- Use learnings to refine tool specs for future jobs.

What a lifecycle footprint infographic should show

A compact visual that helps decision makers at a glance:

- Inputs: water (L/meter), chemical additives, diesel for pumps/rig.

- Onsite footprints: pumped fluid, cuttings mass, truck movements.

- Emissions: CO2 from fuel + embodied emissions of consumables.

- Savings areas: color-coded overlays showing where bit selection, reamer geometry, and hydraulics reduce each input.

- Outcome: CO2 and cost per meter before & after tool optimization.

Final Thoughts — Start with Measurable Pilots

Procurement and sustainability teams should pilot low-footprint tooling on a single well or project. Capture baseline metrics, select tooling to match the formation, optimize hydraulics, and measure results. The combination of improved tools + disciplined circulation practice consistently returns rapid payback: lower costs, fewer regulatory headaches, and a smaller environmental footprint.

Want a turnkey start? At Rockpecker, we are committed to being a pivotal part of this sustainable evolution. We believe that by providing robust, efficient, and technologically advanced drilling solutions, we empower our partners to achieve their operational objectives with a demonstrably lighter environmental touch.

The future of subsurface access is efficient, precise, and environmentally responsible, and it is being shaped, one innovative tool at a time, by organizations dedicated to pushing the boundaries of what's possible in the downhole environment. The adoption and continuous development of these tools are not just good for the planet; they are fundamentally good for the economics and long-term viability of the energy industry.