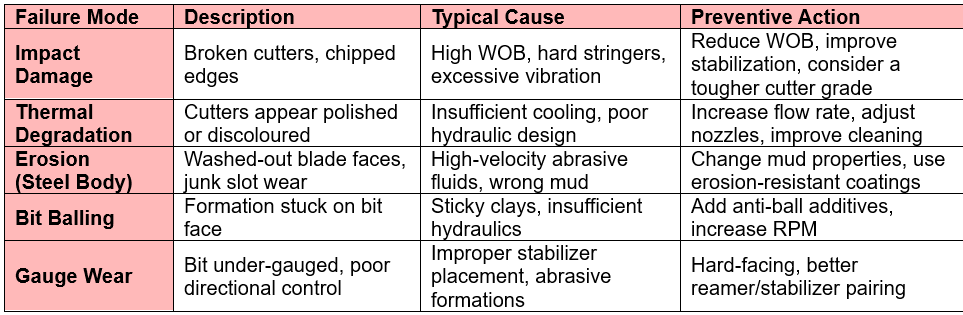

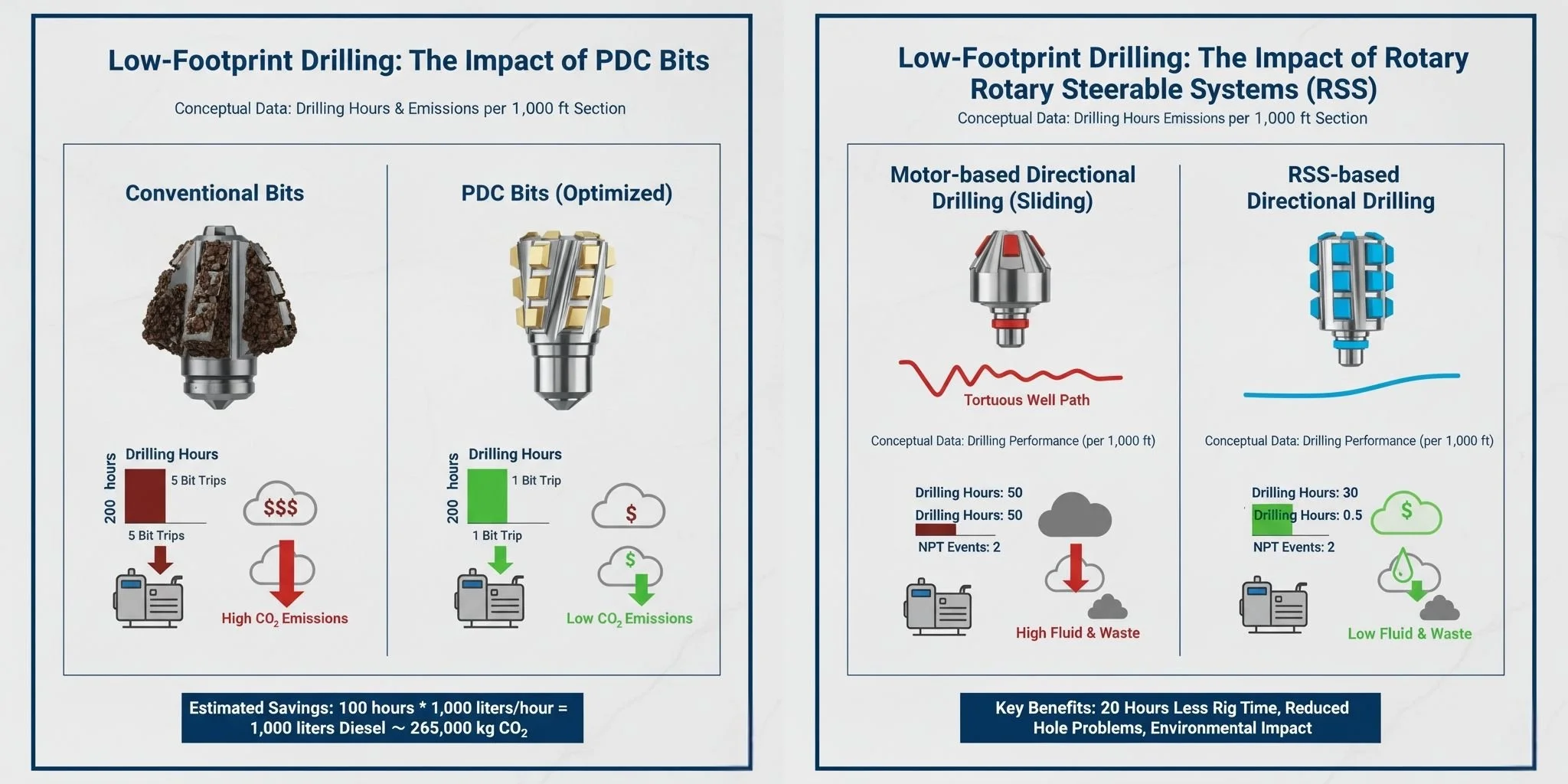

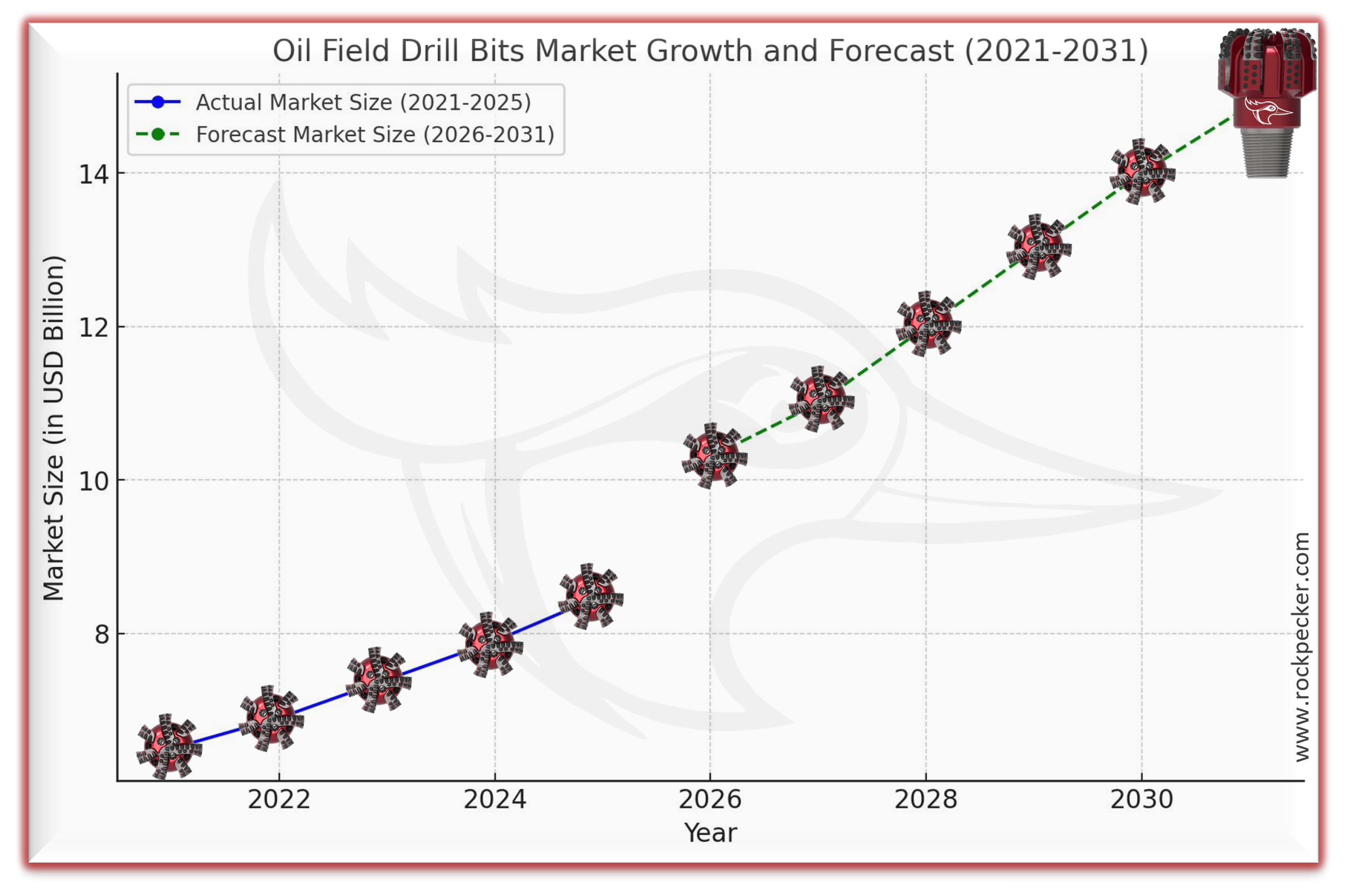

As the curtain closes on 2025, the global drilling landscape looks fundamentally different than it did even three years ago. We have entered an era where "making a hole" is no longer the objective; the objective is total system efficiency. For decades, drilling tools like bits, reamers, and stabilizers, were treated as commodities: interchangeable, price-sensitive consumables that were bought in bulk. However, 2025 marked a definitive turning point. As project environments became harsher and ESG mandates stricter, the industry realized that a "cheap" commodity tool is often the most expensive component on a rig when it leads to premature failure or suboptimal Rate of Penetration. Today, the drill bit is no longer a consumable; it is a precision-engineered component vital to the digital and mechanical integrity of the entire drilling operation.

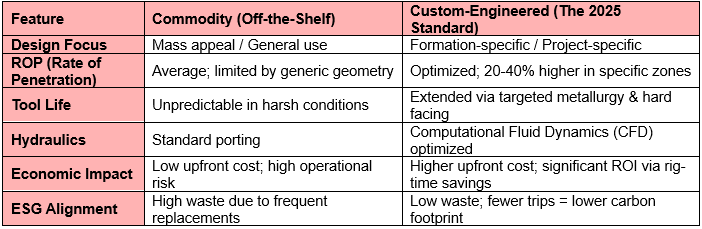

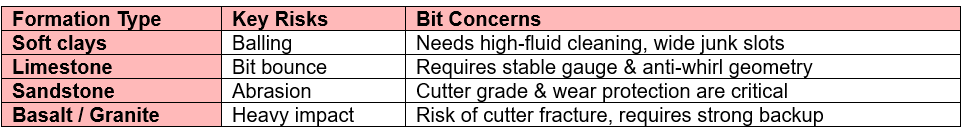

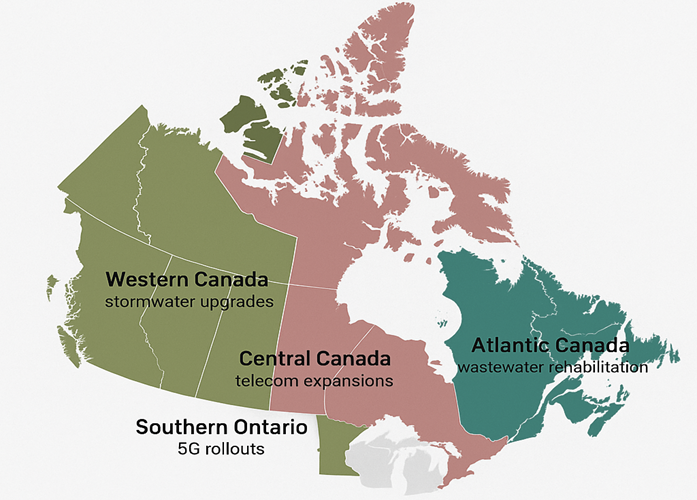

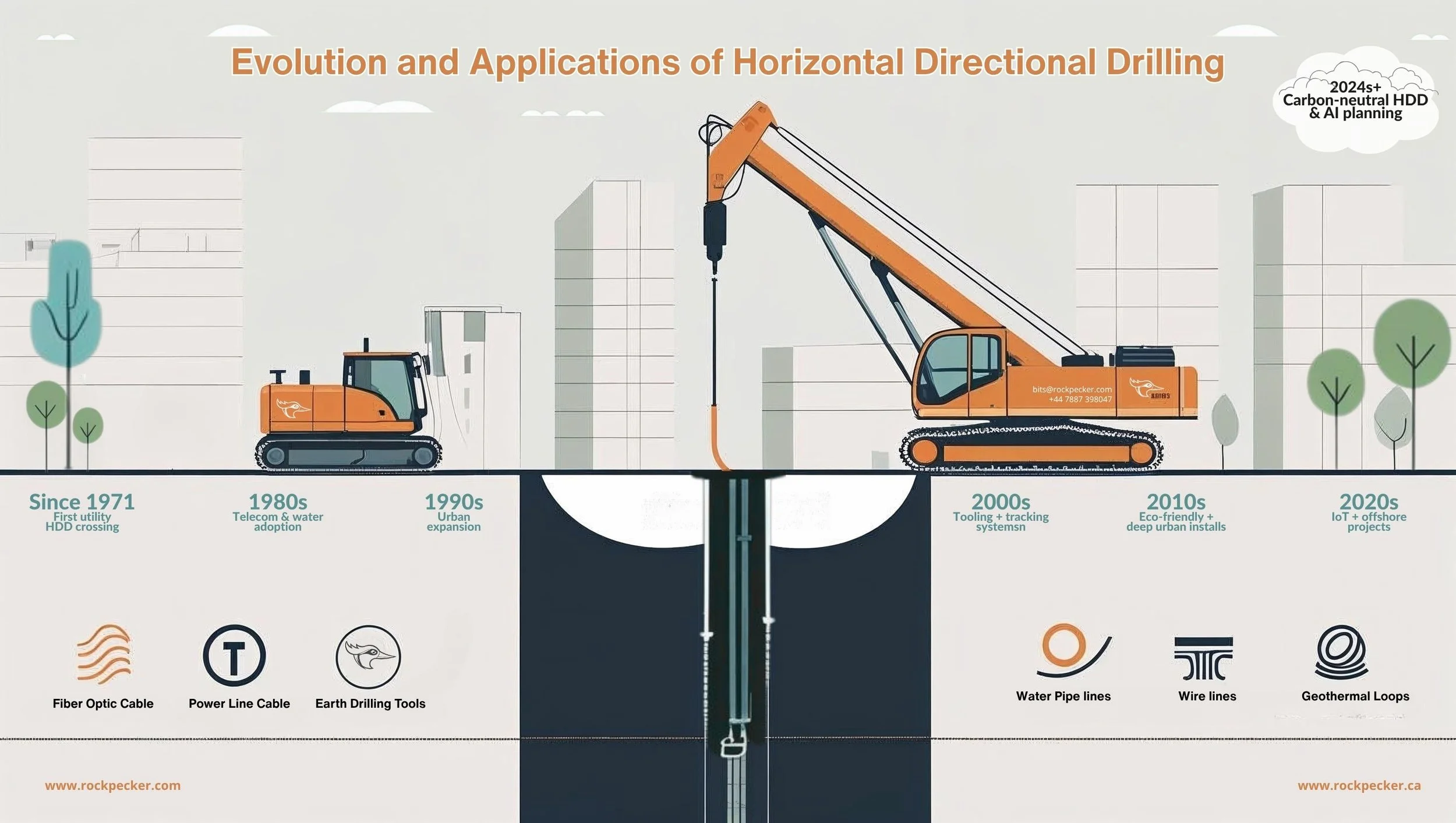

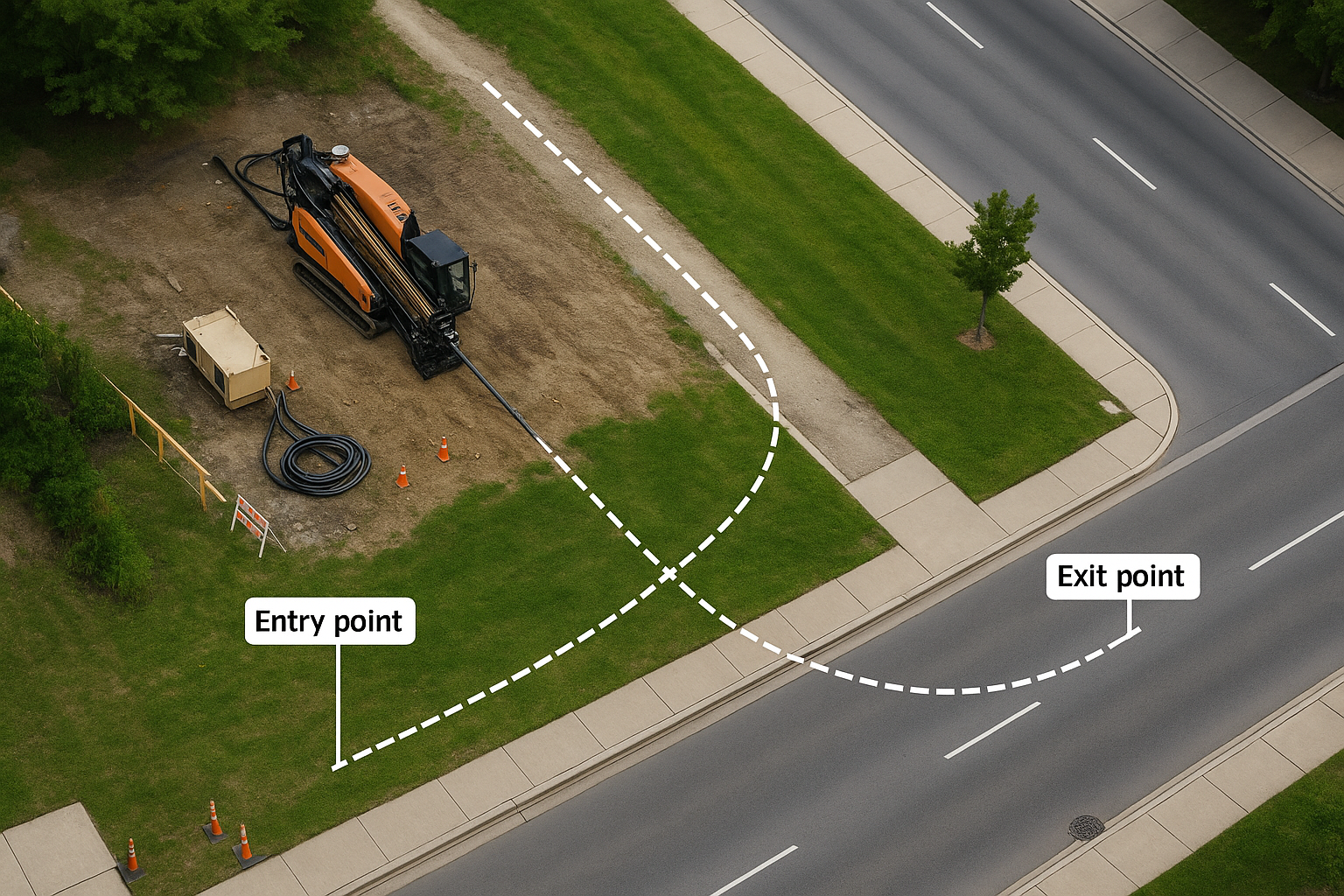

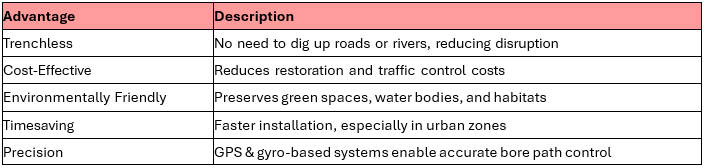

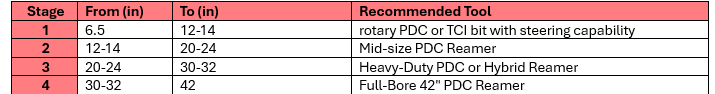

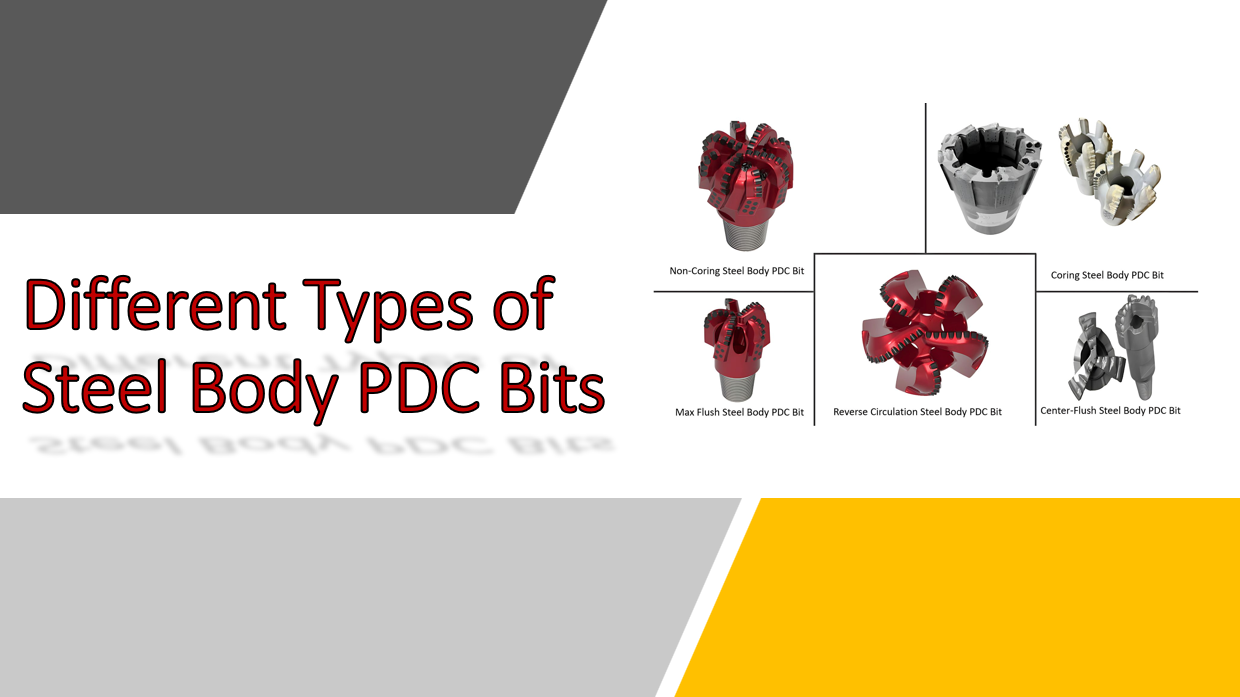

The Death of the "Off-the-Shelf" Mentality: The shift toward customization has been driven by a simple reality: the "easy" holes have already been drilled. Whether it is deep-water Oil & Gas exploration, complex urban HDD (Horizontal Directional Drilling) for smart city infrastructure, or high-temperature geothermal wells, the geological challenges of 2025 have outpaced the capabilities of generic tooling.

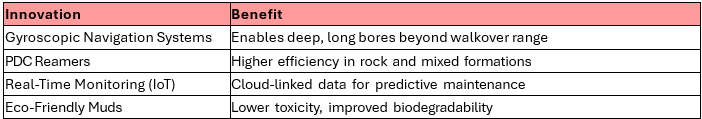

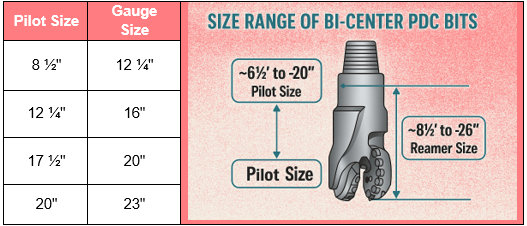

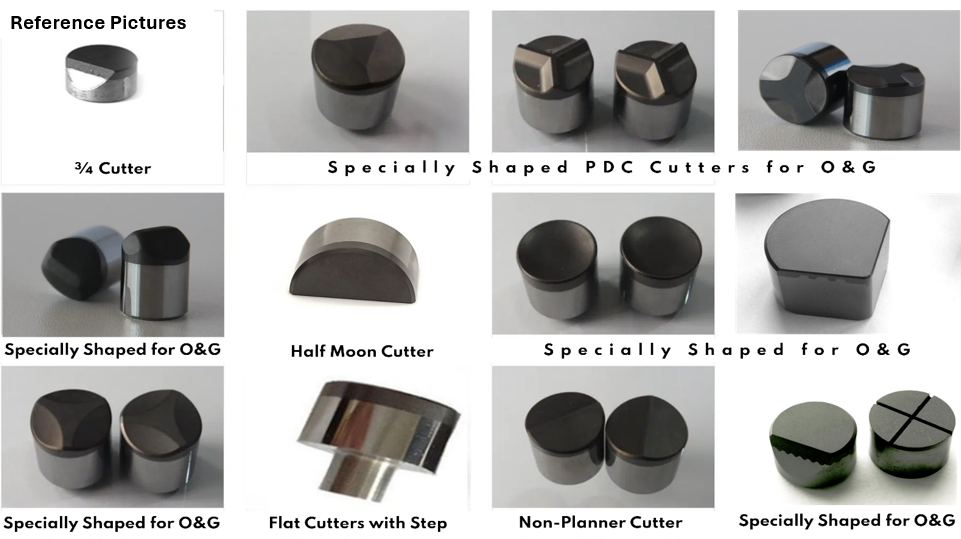

In the past, a driller might accept a standard PDC bit and adjust their drilling parameters to match the tool. In 2025, the script has flipped. Leading operators now demand tools that are designed to match the formation. This "bespoke" approach ensures that every cutter angle, every hydraulic port, and every millimetre of blade geometry is optimized for the specific rock strength and temperature of the project at hand.

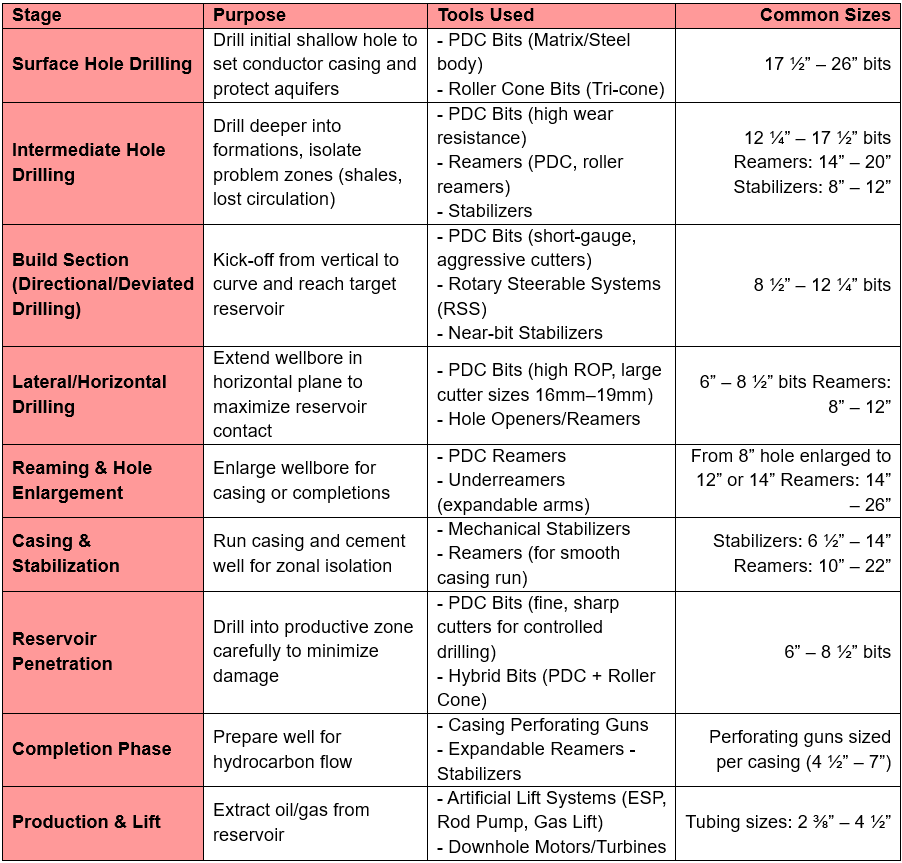

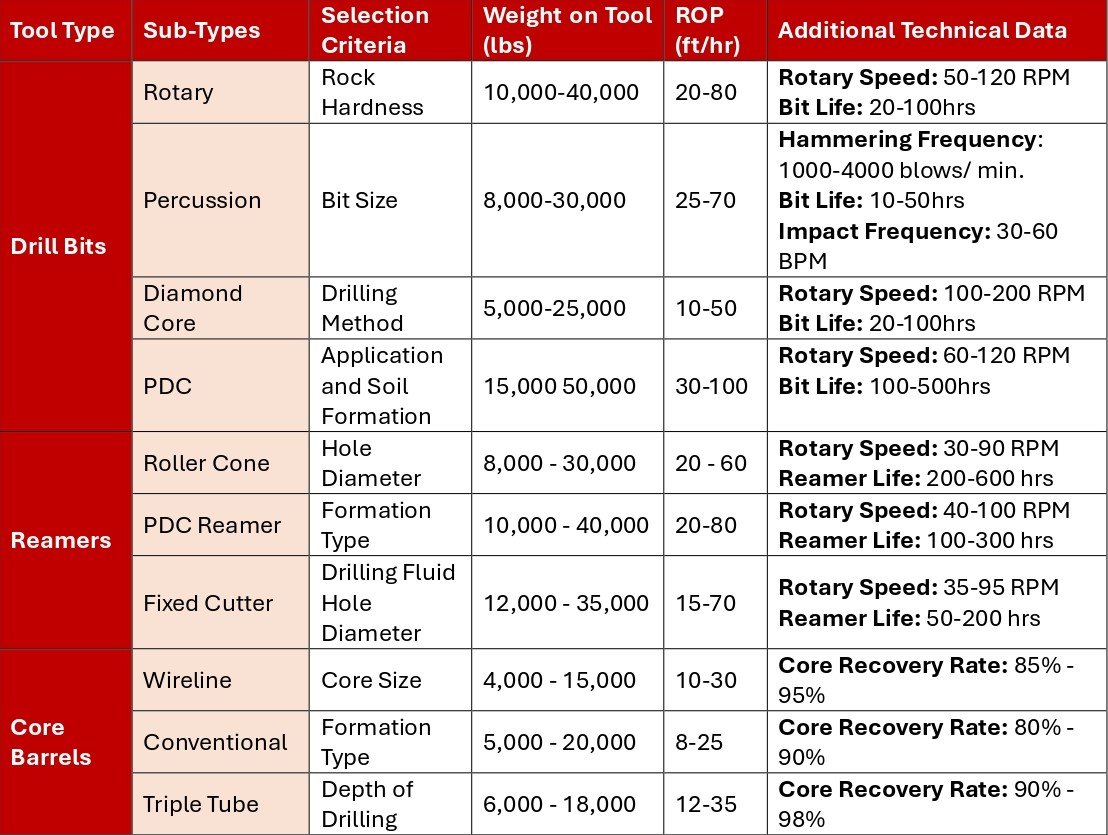

Figure 1: From Commodity to Component: Why 2025 Saw a Shift Toward Custom-Engineered Tooling

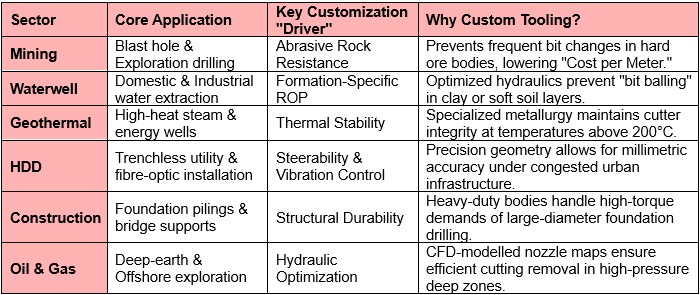

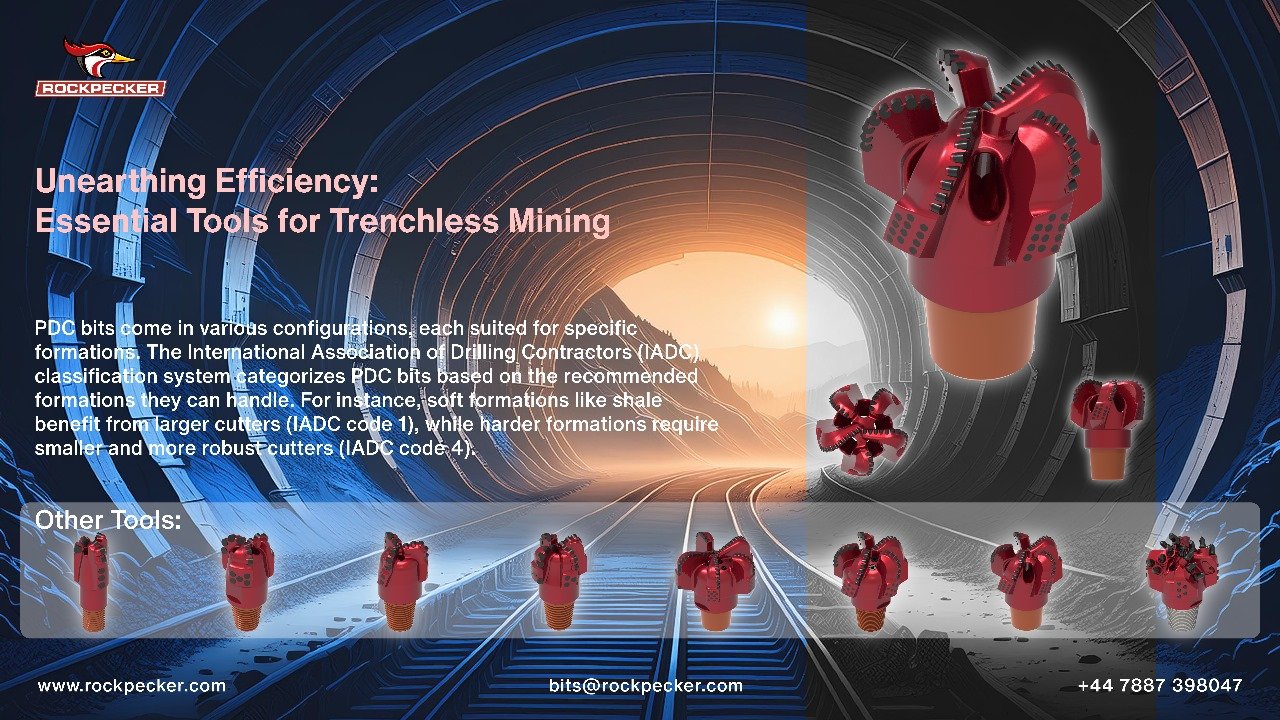

Sector-Specific Drivers for Customization: The demand for custom-engineered tools isn't limited to a single niche; it is a cross-industry revolution. At Rockpecker, we have observed this trend accelerating across all major drilling verticals:

1. Oil, Gas & Geothermal: The Battle Against Heat and Pressure In High-Temperature, High-Pressure (HTHP) environments, standard elastomers and traditional metallurgy fail. 2025 saw a surge in demand for custom bits featuring proprietary hard facing and specialized cutter grades. For geothermal energy—the "hot" topic of the year—tools must withstand abrasive igneous rock while maintaining integrity at temperatures exceeding 200°C. A custom-engineered bit isn't just a choice here; it is a prerequisite for reaching Total Depth.

Oil and Gas: By customizing nozzle placement and junk slot geometry, Rockpecker ensures that fluid flows precisely where it is needed to cool cutters and evacuate cuttings instantly, preventing "bit balling" and ensuring the tool survives the entire interval without an expensive trip to the surface.

Geothermal: Customization here focuses on proprietary hard facing and heat-stabilized cutter grades. While a commodity bit might lose its cutting edge within hours, a tool specifically engineered for geothermal heat remains sharp, maintaining the high ROP required to make geothermal projects economically viable.

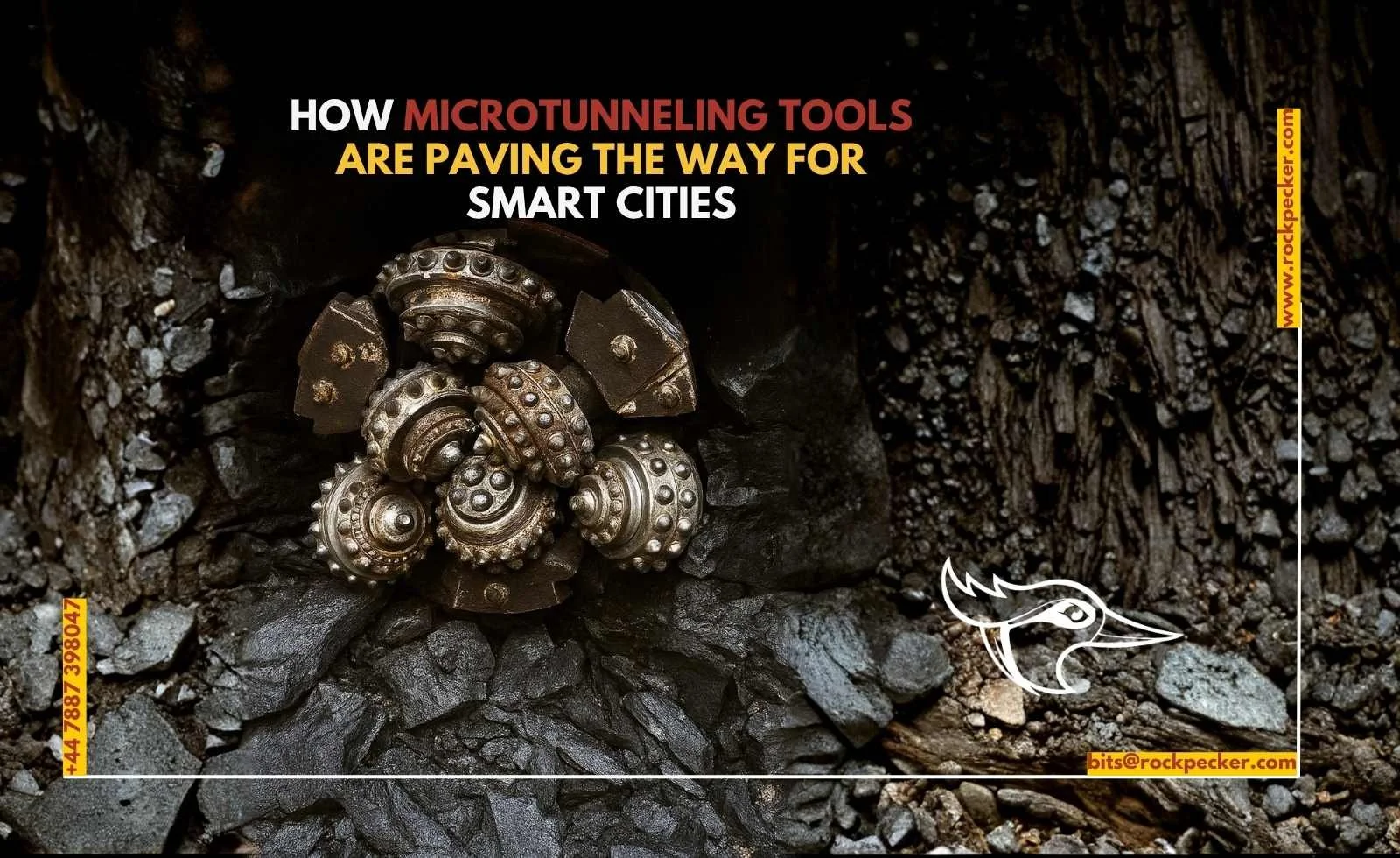

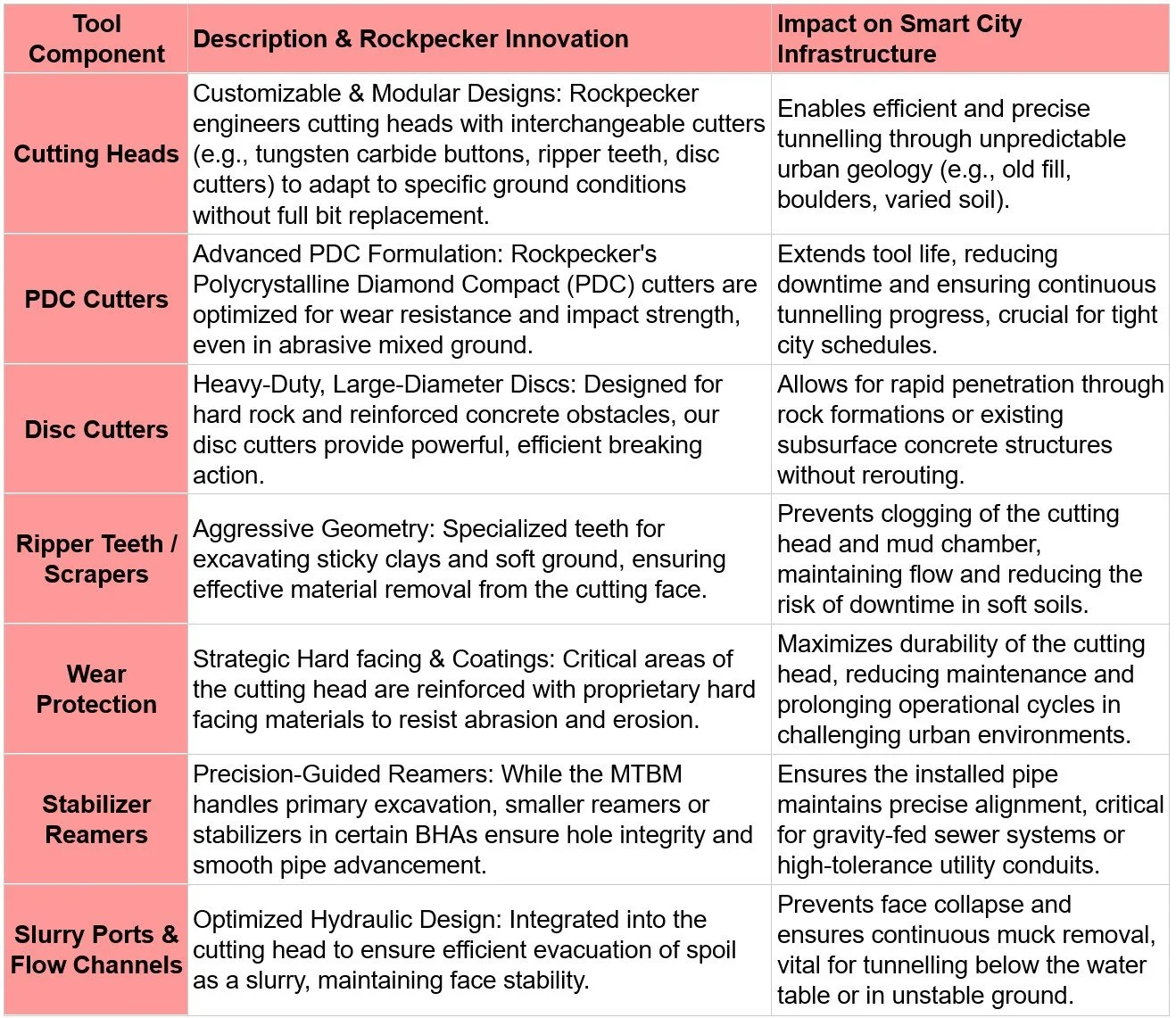

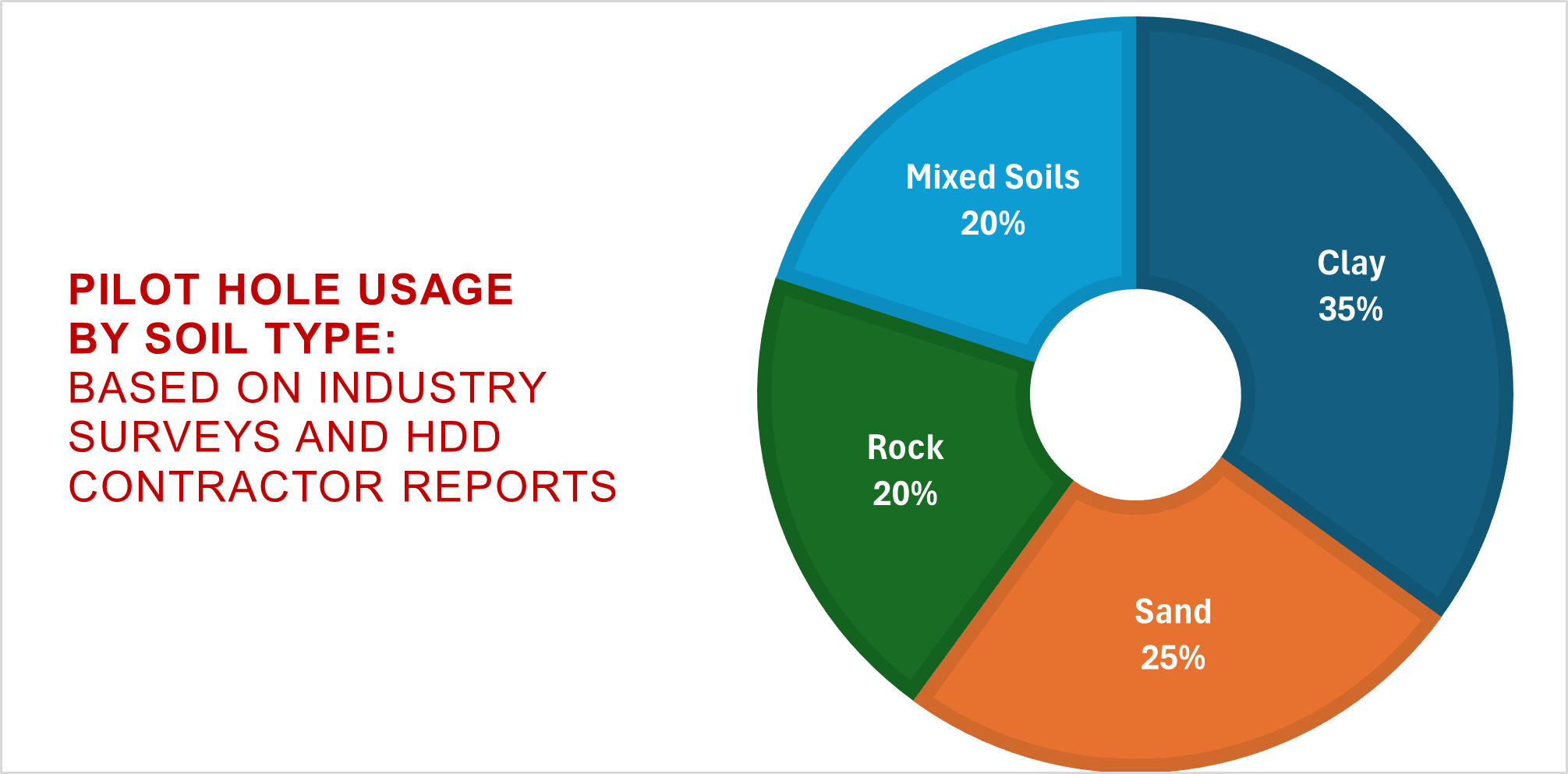

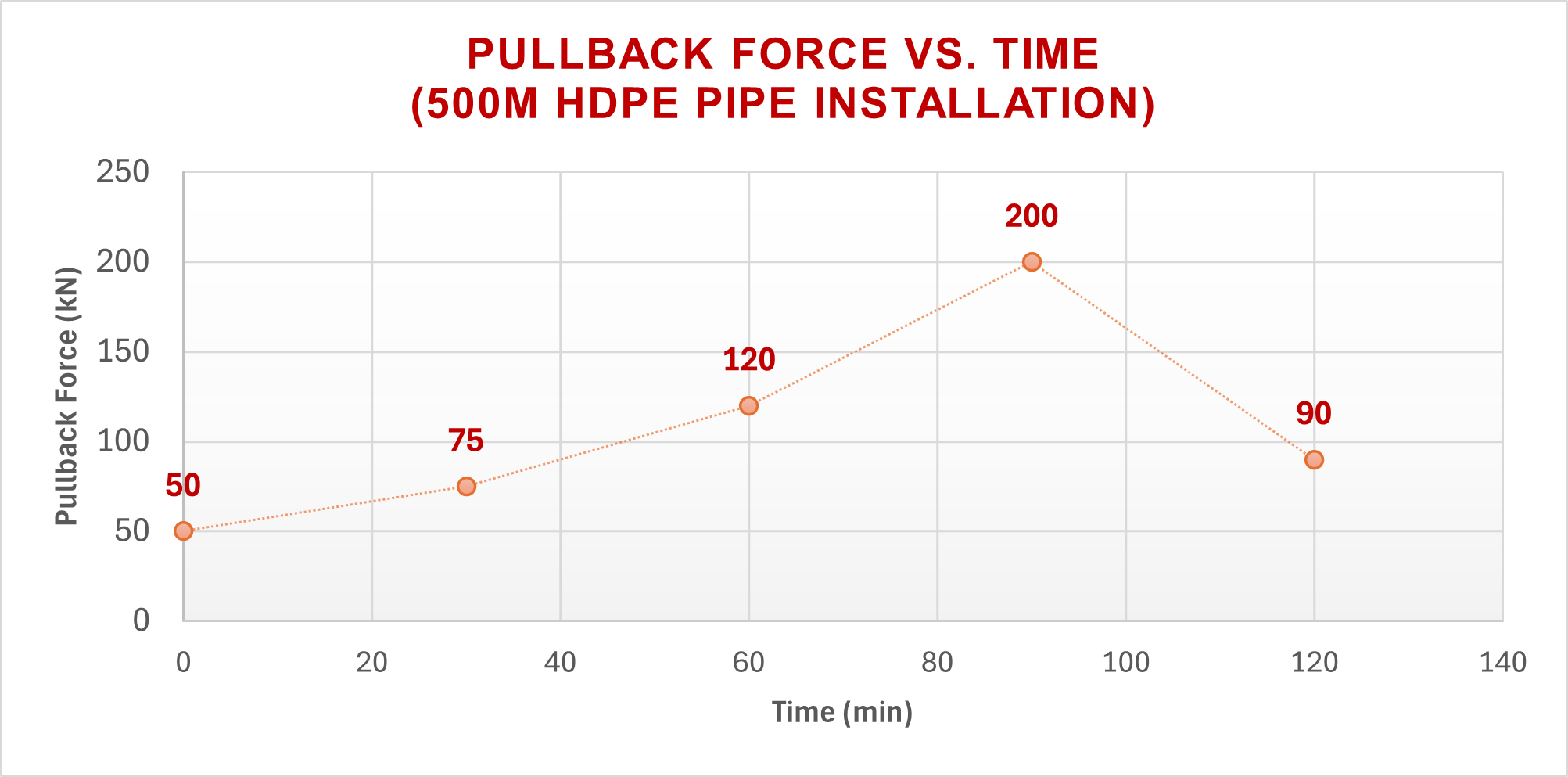

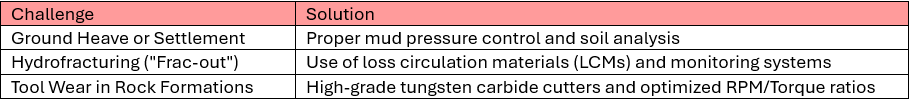

2. HDD and Urban Construction: Precision in Tight Spaces These are now operating in "congested undergrounds." When drilling beneath a metropolitan center, there is zero margin for error. Custom-engineered reamers and cutting heads allow for better steerability and vibration control, protecting existing fibre-optic and utility lines while maintaining the precision required for smart-city conduits.

- HDD: We customize the cutter density and diamond table thickness to match the specific geology of the mine. This bespoke approach allows mining contractors to achieve a lower "Total Cost of Ownership" (TCO), as the tools last longer and drill faster than generic alternatives.

- Construction: Our mastery in customization allows us to design steerable reamers and cutting heads with optimized balance. This reduces vibration and ensures the tool follows the planned path with millimetric accuracy.

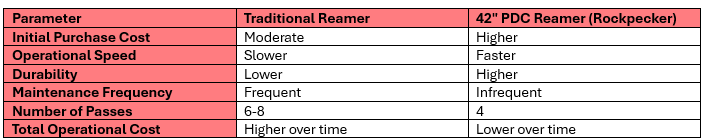

3. Mining and Waterwell: The Efficiency Mandate In mining, the goal is "Lowest Cost per Meter." Generic tools often lead to inconsistent performance. By customizing the bit profile and cutter density to the specific ore body, mining operators in 2025 have seen a dramatic reduction in "tripping time"—the costly process of pulling the drill string to replace a worn-out bit.

Rockpecker specializes in hybrid designs that combine the aggressive cutting action of PDC with the durability required for rocky transitions. This ensures that even smaller contractors can complete their projects on time without needing to switch tools every few hundred feet.

Figure 2: Sector-Specific Drivers for Customization

Figure 3: Application or Sector-Specific Drivers for Customization

The Pillars of Customization & how it is done: To move from commodity to component, three technical pillars must be addressed:

Advanced Metallurgy: Moving beyond standard steel to proprietary alloys that resist thermal degradation and abrasion.

Hydraulic Precision: Using CFD to ensure that drilling mud cools the cutters and removes cuttings efficiently, preventing "bit balling" and heat checking.

Cutter Technology: Not all diamonds are created equal. Customization allows for the selection of specific PDC cutter grades (leached vs. non-leached, thick vs. thin diamond tables) based on the impact and abrasion profile of the rock.

Figure 4: Commodity (Off-the-Shelf) v/s Custom-Engineered (The 2025 Standard) Features

Conclusion: Positioning for 2026: As we look toward 2026, the drilling industry will continue to reward precision over volume. The "Commodity Era" is effectively over, replaced by a value-driven model where the quality of the downhole component dictates the success of the multi-million-dollar asset above it. For project owners and drilling contractors, the message of 2025 is clear: invest in the tool that is engineered for your challenge, not the one that was engineered for the average.

At Rockpecker, we don’t just manufacture tools; we engineer solutions for the most complex subsurface environments on Earth. From HDD and construction to the depths of the Oil & Gas sector, our mastery of customization ensures that your project isn't just completed—it's optimized.